.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

In the highly competitive glass industry, enhancing production efficiency and reducing costs are paramount concerns for global glass manufacturers. These challenges have led to a continuous search for advanced refractory materials, and zircon mullite bricks have emerged as a game - changing solution.

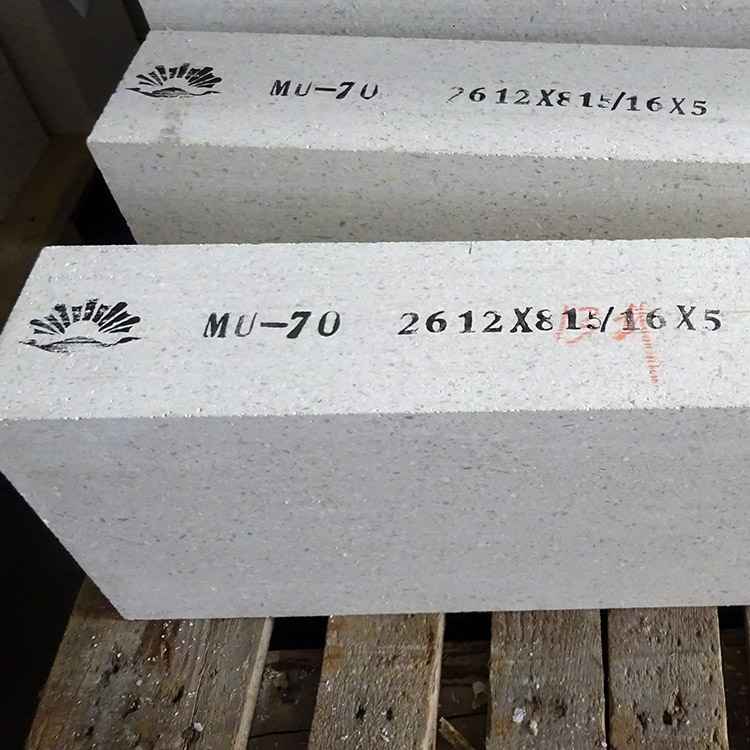

Zircon mullite bricks are crafted from fused zircon mullite and sintered alumina through high - temperature sintering processes. This unique combination of raw materials endows the bricks with high density and purity, which are the fundamental factors for their excellent performance.

The glass manufacturing process involves rapid temperature changes. Zircon mullite bricks can withstand sudden temperature fluctuations of up to 1000°C without significant damage. This excellent thermal shock resistance ensures their long - term stability in the harsh environment of glass furnaces, reducing the frequency of brick replacements.

In high - temperature and chemically active glass furnace atmospheres, traditional refractory materials often suffer from spalling. Zircon mullite bricks, however, exhibit remarkable spalling resistance. Their dense structure and stable chemical properties prevent the penetration of molten glass and other corrosive substances, effectively extending their service life.

The strong corrosion resistance of zircon mullite bricks is a significant advantage. They can resist the erosion of various glass melts, including soda - lime glass, borosilicate glass, and aluminosilicate glass. Tests have shown that zircon mullite bricks can reduce the corrosion rate by up to 50% compared to some traditional refractory materials.

.jpg)

When compared with traditional refractory materials such as clay bricks and high - alumina bricks, zircon mullite bricks offer several distinct advantages. Traditional materials often have lower density and purity, resulting in poorer thermal shock resistance, spalling resistance, and corrosion resistance. This leads to more frequent maintenance and replacement, which significantly increases production costs. In contrast, zircon mullite bricks can operate continuously for up to 5 - 7 years in a glass furnace, while traditional materials may need to be replaced every 1 - 2 years.

A well - known glass manufacturer in Europe replaced their traditional refractory materials with zircon mullite bricks in their glass furnace. After the replacement, they witnessed a 20% increase in production efficiency due to reduced downtime for maintenance. Moreover, their production costs were cut by approximately 15% over a year, mainly because of the extended service life of the bricks and the decrease in replacement frequency.

In Asia, a large - scale glass factory adopted zircon mullite bricks and reported a significant improvement in product quality. The reduced corrosion of the bricks meant fewer impurities were introduced into the glass melt, resulting in higher - quality glass products.

In conclusion, zircon mullite bricks are an indispensable key product in the glass industry. Their excellent thermal shock resistance, spalling resistance, and corrosion resistance can effectively enhance production efficiency and reduce costs for glass manufacturers. By choosing zircon mullite bricks, you are making a strategic investment in the long - term success of your glass production.