In the demanding environment of glass production, refractory materials face relentless challenges from high-temperature corrosive glass melts and the risk of material adhesion that leads to clogging. Finding a refractory that can withstand these conditions while maintaining performance is critical for continuous and efficient glass melting operations. AZS33 fused cast blocks stand out as a leading solution, offering exceptional durability and stability when exposed to aggressive glass liquids.

\n\nGlass melting furnaces operate at temperatures often exceeding 1500°C. At such extremes, molten glass aggressively attacks refractories, leading to corrosion that shortens the lifespan of furnace linings. Furthermore, the formation of glass “fins” or solidified layers on refractory surfaces can cause troublesome blockages, compromising production throughput and product uniformity.

\n\nTraditional refractory materials may struggle to balance corrosion resistance and anti-adhesion features, creating operational vulnerabilities. AZS33 is engineered to address these dual challenges through its unique chemistry and microstructure.

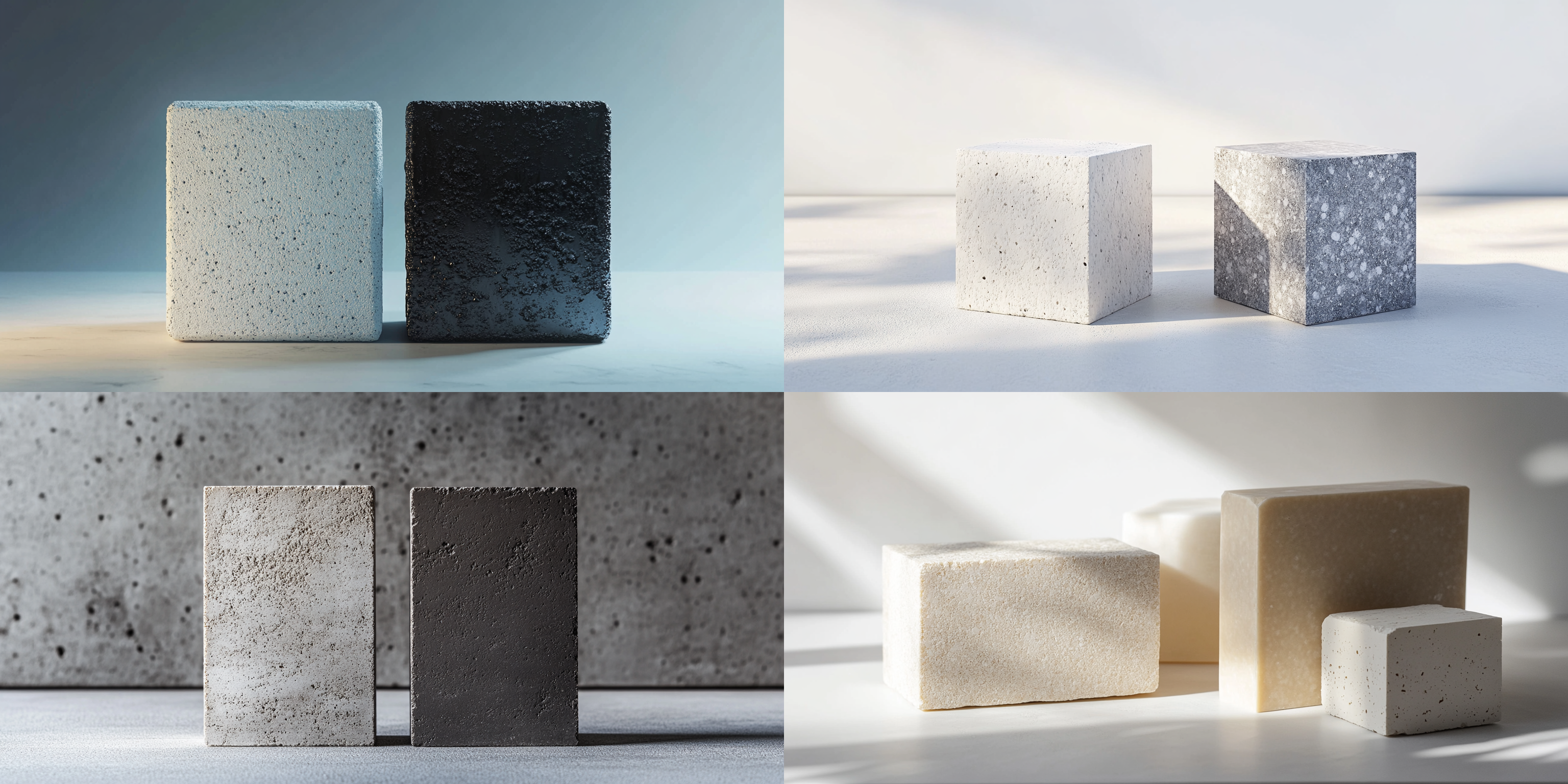

\n\nAZS33 is composed primarily of high-purity alumina (Al₂O₃) powder combined with carefully processed zircon sand, which contains approximately 65% zirconia (ZrO₂) and 34% silica (SiO₂). This precise formulation leverages the complementary properties of these oxides:

\n\nMaterials science principles confirm that the Al₂O₃-ZrO₂-SiO₂ combination creates a highly dense microstructure, minimizing pathways for corrosive glass to penetrate. This densification also significantly reduces the surface energy, helping to resist glass adhesion and block formation.

\n\n \n

\n

Electron microscopy analyses reveal AZS33's microstructure is characterized by tightly interlocked grains of alumina and zirconia embedded in a finely dispersed silica matrix. This structure is markedly more compact than many competing refractory types.

\n\nSuch microstructural compactness delivers two principal benefits:

\n\n| Property | \nBenefit to AZS33 Performance | \n

|---|---|

| High Density & Low Porosity | \nMinimizes chemical infiltration from molten glass, dramatically reducing corrosion rate. | \n

| Uniform Grain Distribution | \nPrevents nucleation sites for glass crystallization, decreasing the risk of blockages from glass solidification on surfaces. | \n

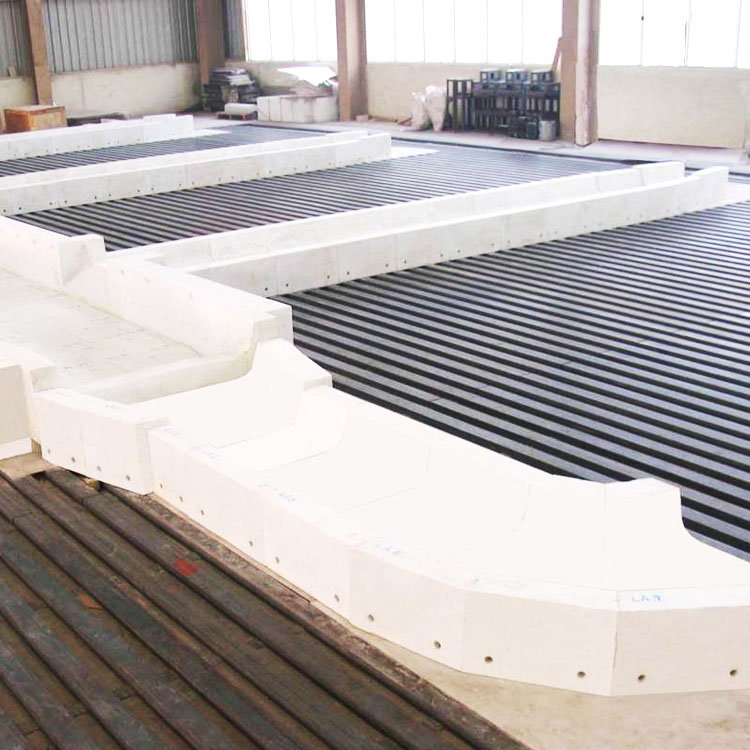

Thanks to its robust chemical and structural qualities, AZS33 is widely used in critical zones of glass melting furnaces — including the upper furnace structure, sidewalls, and especially feeding channels which are prone to fouling. Its excellent anti-corrosive and anti-blocking properties ensure operational stability, fewer shutdowns, and longer campaign lifetimes.

\n\n.jpg) \n

\n

Several global glass manufacturers have reported remarkable improvements after adopting AZS33 refractory blocks.

\n\nFor instance, a European container glass producer documented a 25% extension in refractory life within their melting furnace's upper structure, paired with a 15% reduction in unplanned downtime caused by glass blockages. This translated to annual savings surpassing six figures in avoided maintenance and lost production.

\n\nAnother case in the flat glass sector showed AZS33 reducing corrosion damage by nearly 40%, enabling stable operation at higher throughput and improving final glass surface quality by decreasing contamination.

\n\n \n

\n

AZS33’s scientifically optimized composition combining pure alumina powder with zircon sand rich in zirconia and silica achieves a uniquely dense and resilient microstructure. This innovation addresses the toughest challenges in glass melting by enhancing corrosion resistance and preventing glass adhesion, leading to less downtime, longer furnace campaigns, and improved product quality.

\n\nFor glass manufacturers seeking stable and efficient production, investing in AZS33 fused cast refractory blocks is a strategic choice backed by material science and proven industrial success.

\n\n \n\n