When it comes to selecting refractory materials, global buyers often find themselves in a maze of choices. The high - temperature industrial environment demands products that can withstand extreme conditions, and choosing the wrong refractory can lead to increased costs, reduced efficiency, and potential safety hazards. Among the various refractory options, mullite bricks stand out as a popular choice. However, understanding the different types of mullite bricks, specifically sintered mullite bricks and fused mullite bricks, is crucial for making an informed decision.

Sintered mullite bricks are typically made from high - alumina bauxite, clay, and other natural minerals. These raw materials are first crushed, milled, and then mixed in specific proportions. The mixture is then formed into brick shapes through pressing or extrusion methods. After shaping, the bricks are dried and fired at high temperatures, usually between 1600°C - 1800°C, to achieve sintering.

In terms of performance, sintered mullite bricks have good thermal shock resistance, with the ability to withstand temperature fluctuations of up to 100 - 150 times in a normal industrial environment. They also have a relatively high porosity, which can reach about 18% - 22%, providing good insulation properties. Their refractoriness is generally above 1750°C, making them suitable for medium - to high - temperature applications.

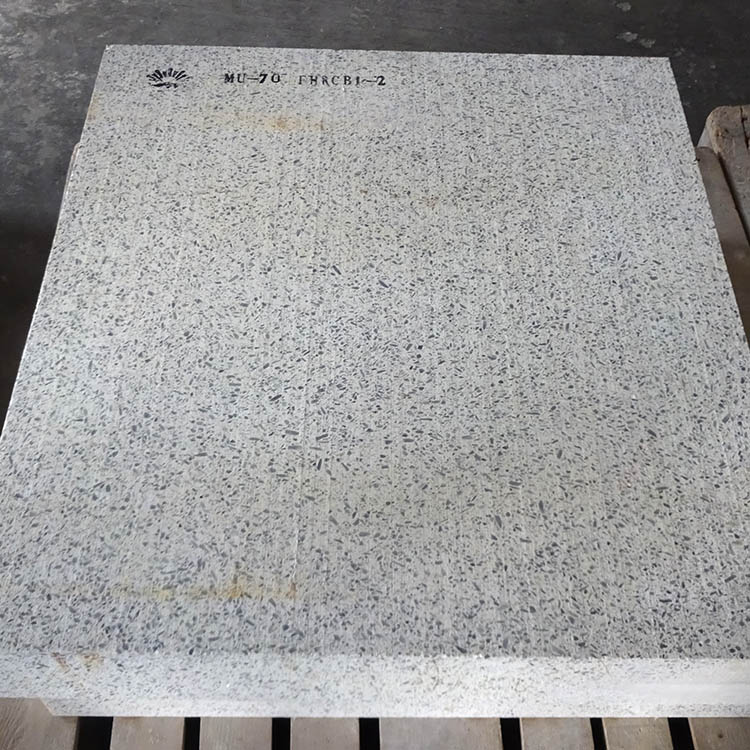

Fused mullite bricks are produced using high - purity alumina and silica as the main raw materials. These materials are melted in an electric arc furnace at extremely high temperatures, often exceeding 2000°C. Once melted, the molten material is poured into molds and allowed to solidify slowly. This process results in a dense and homogeneous structure.

Fused mullite bricks have excellent corrosion resistance. In a corrosive industrial environment, they can maintain their integrity for up to 3 - 5 years, which is significantly longer than many other refractory materials. They also have a very low porosity, usually less than 5%, and high mechanical strength, making them suitable for high - pressure and high - temperature applications. Their refractoriness can reach over 1850°C.

| Aspect | Sintered Mullite Bricks | Fused Mullite Bricks |

|---|---|---|

| Raw Materials | High - alumina bauxite, clay | High - purity alumina and silica |

| Production Process | Crushing, mixing, pressing, sintering at 1600 - 1800°C | Melting in electric arc furnace above 2000°C, pouring into molds |

| Porosity | 18% - 22% | Less than 5% |

| Refractoriness | Above 1750°C | Over 1850°C |

| Thermal Shock Resistance | Good, withstands 100 - 150 temperature fluctuations | Relatively lower compared to sintered |

| Corrosion Resistance | Moderate | Excellent, lasts 3 - 5 years in corrosive environment |

In the metallurgical industry, where high - temperature melting and refining processes are common, fused mullite bricks are often used in the lining of electric arc furnaces and ladles due to their high refractoriness and corrosion resistance. Sintered mullite bricks, on the other hand, are suitable for areas with less extreme temperature and corrosion requirements, such as the pre - heating zones of furnaces.

In the glass industry, the production of glass involves high - temperature melting and forming processes. Fused mullite bricks can be used in the glass melting tanks, where they can withstand the high temperatures and the corrosive effects of molten glass. Sintered mullite bricks can be applied in the insulation layers of the glass furnaces, providing thermal insulation and reducing energy consumption.

In conclusion, sintered mullite bricks and fused mullite bricks have distinct characteristics and are suitable for different industrial applications. Sintered mullite bricks offer good thermal shock resistance and insulation, making them ideal for medium - temperature and less corrosive environments. Fused mullite bricks, with their high refractoriness, low porosity, and excellent corrosion resistance, are better suited for high - temperature and high - pressure applications.

Choosing the right mullite brick according to your specific needs is crucial for optimizing the performance and longevity of your high - temperature equipment. Our company offers a wide range of high - quality sintered and fused mullite bricks. If you are looking for reliable refractory solutions, contact us today to find the perfect mullite brick product for your application!