When it comes to procuring refractory materials, many global buyers often find themselves in a quandary. With a plethora of options available in the market, making the right choice can be a daunting task. Among these options, mullite bricks stand out as a popular choice due to their excellent refractory properties. In this article, we will delve into the classification and characteristics of mullite bricks, aiming to assist you in making a precise procurement decision.

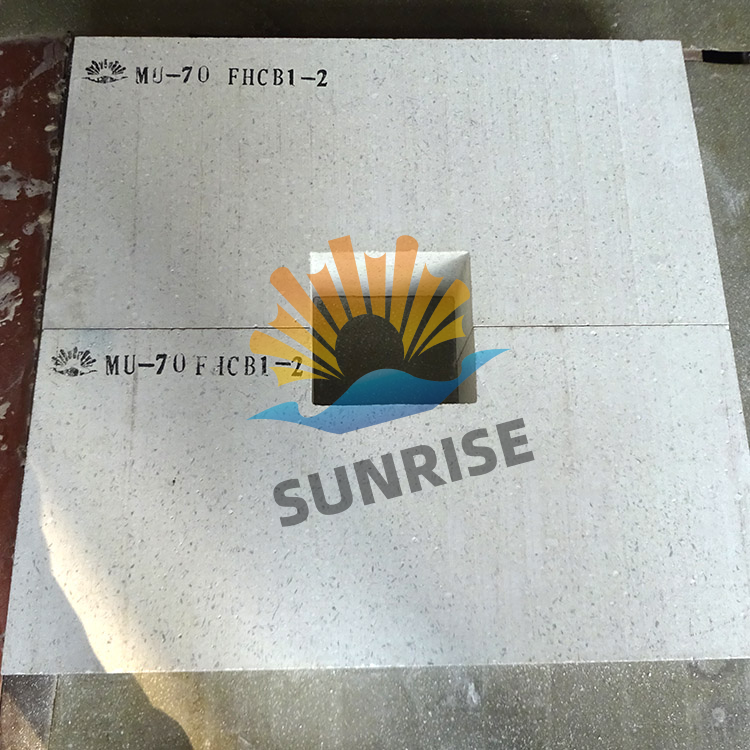

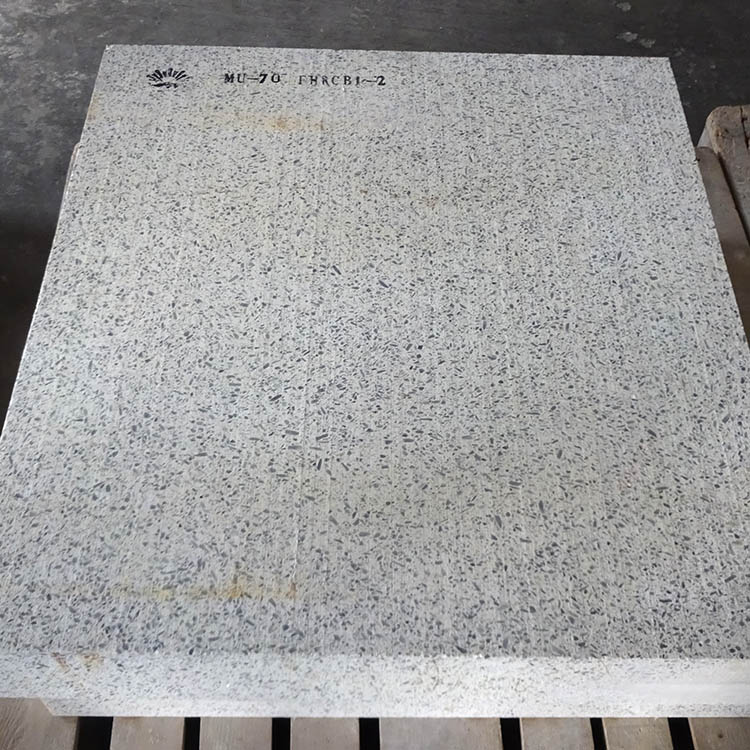

Mullite bricks are a type of high - quality refractory material widely used in various industries. There are two main types: sintered mullite bricks and fused mullite bricks. Let's explore their raw materials, manufacturing processes, and performance characteristics.

The raw materials for sintered mullite bricks mainly include high - alumina bauxite, kaolin, and other aluminosilicate minerals. These raw materials are first crushed and milled into fine powder. Then, appropriate binders are added, and the mixture is pressed into brick shapes. Subsequently, the green bricks are sintered at high temperatures, usually around 1600 - 1800°C. This high - temperature sintering process forms a stable crystal structure, endowing the bricks with good thermal shock resistance and mechanical strength. In fact, sintered mullite bricks can withstand thermal shock up to 10 - 15 times at a temperature difference of 800 - 1000°C, according to industry statistics.

Fused mullite bricks are made from high - purity alumina and silica raw materials. These materials are melted in an electric arc furnace at extremely high temperatures, typically above 2000°C. After melting, the molten material is poured into a mold and cooled slowly to form a dense and uniform crystal structure. Fused mullite bricks have higher density and better corrosion resistance compared to sintered mullite bricks. They can resist the corrosion of alkaline slag and acidic slag to a large extent, making them suitable for harsh chemical environments. Industry data shows that the corrosion rate of fused mullite bricks in alkaline slag is only about 5 - 10% of that of ordinary refractory bricks.

In terms of composition, fused mullite bricks have a higher purity of mullite phase, while sintered mullite bricks may contain some impurities from the raw materials. In the manufacturing process, the high - temperature melting of fused mullite bricks results in a more homogeneous structure. Regarding performance, fused mullite bricks excel in corrosion resistance, while sintered mullite bricks are better at thermal shock resistance.

In the metallurgical industry, sintered mullite bricks are often used in the lining of steel ladles and tundishes due to their good thermal shock resistance. Fused mullite bricks are preferred in the glass industry for glass melting furnaces, as they can withstand the high - temperature and corrosive environment. In the ceramic industry, both types can be used in kilns, with sintered mullite bricks suitable for areas with frequent temperature changes and fused mullite bricks for parts in contact with molten materials.

In conclusion, choosing the right type of mullite brick depends on your specific requirements. Whether you need high thermal shock resistance or excellent corrosion resistance, understanding the characteristics of sintered and fused mullite bricks is crucial. Our company offers high - quality sintered and fused mullite bricks that meet international standards. Don't miss out on the opportunity to enhance your industrial operations with our top - notch refractory solutions. Click here to explore our mullite brick products and make a smart purchase!