In the ever - evolving landscape of the coke industry, the demand for high - performance refractory materials for coke ovens has reached new heights. As coke production processes become more complex and demanding, the quality of refractory materials directly impacts the efficiency, lifespan, and overall profitability of coke ovens. This article serves as a comprehensive guide for procurement decision - making, focusing on high - density, low - porosity silica bricks and their significant role in enhancing coke oven performance.

The coke industry has witnessed remarkable growth in recent years, driven by the increasing demand for steel production. With the expansion of production capacity and the improvement of production technology, coke ovens are now operating under more severe conditions, such as higher temperatures, greater pressure, and more frequent thermal cycling. These harsh conditions pose a significant challenge to traditional refractory materials, highlighting the need for advanced solutions.

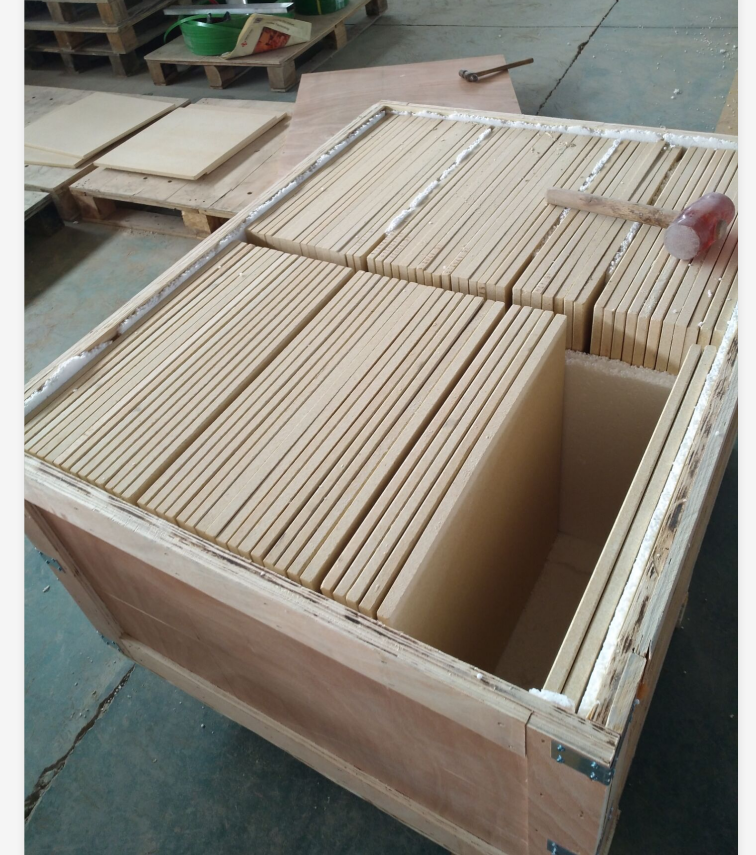

High - density, low - porosity silica bricks are a revolutionary product in the field of refractory materials. Their core characteristics include high density, high thermal conductivity, and high compressive strength at high temperatures.

The high density of these silica bricks means fewer pores and a more compact structure. This characteristic enhances the brick's resistance to corrosion, erosion, and thermal shock. For example, compared with ordinary silica bricks, high - density silica bricks have a porosity that is 15% - 20% lower, which significantly improves their durability.

High thermal conductivity allows for more efficient heat transfer within the coke oven. This property helps to maintain a more uniform temperature distribution inside the oven, reducing the risk of local overheating and extending the lifespan of the oven. Tests have shown that high - density, low - porosity silica bricks can increase the thermal conductivity by 10% - 15% compared to traditional silica bricks.

In a high - temperature environment, the coke oven is subject to significant pressure. High - density, low - porosity silica bricks have excellent high - temperature compressive strength, which can withstand the mechanical stress during the coking process. They can maintain a compressive strength of over 50 MPa at temperatures above 1400°C, ensuring the structural integrity of the coke oven.

Through real - world data and case studies, we can clearly see the positive impact of high - density, low - porosity silica bricks on extending the lifespan of coke ovens and improving production efficiency.

In a large - scale coke production plant, after replacing traditional silica bricks with high - density, low - porosity silica bricks, the maintenance cycle of the coke oven was extended from 3 years to 5 years, reducing the frequency of shutdowns for maintenance. At the same time, the production efficiency increased by 8% - 10% due to the more stable operating conditions.

When making a procurement decision, customers are always concerned about the cost - benefit ratio. Although the initial cost of high - density, low - porosity silica bricks is slightly higher than that of traditional silica bricks, the long - term benefits are significant.

| Cost Item | Traditional Silica Bricks | High - Density, Low - Porosity Silica Bricks |

|---|---|---|

| Initial Purchase Cost | $100,000 | $120,000 |

| Maintenance Cost over 5 Years | $80,000 | $30,000 |

| Production Loss due to Shutdown | $50,000 | $10,000 |

| Total Cost over 5 Years | $230,000 | $160,000 |

User feedback also indicates that the application of high - density, low - porosity silica bricks has brought about significant improvements in production efficiency and cost savings. Many customers have reported that the product has met or exceeded their expectations in terms of performance and reliability.

To help customers make a scientific decision, here are some key points to consider:

Firstly, evaluate the specific requirements of your coke oven, such as operating temperature, pressure, and thermal cycling frequency. If your coke oven operates under harsh conditions, high - density, low - porosity silica bricks are a more suitable choice.

Secondly, consider the long - term cost - benefit. Although the initial investment is higher, the reduction in maintenance costs and production losses over the long term can lead to significant savings.

Finally, refer to the experience of other users. Look for case studies and user reviews to understand the actual performance of the product in real - world applications.

By carefully considering these factors, customers can make an informed decision on whether to choose high - density, low - porosity silica bricks to enhance the overall efficiency of their coke ovens.

If you are looking to extend the lifespan of your coke oven, improve production efficiency, and maximize your profits, don't miss out on the opportunity to explore the benefits of high - density, low - porosity silica bricks. Click here to learn more and make the right procurement decision!