In the global glass industry, improving production efficiency and reducing costs have always been the core concerns of manufacturers. Traditional refractory materials have long played a role in glass production, but with the increasing demands of the industry, their limitations are becoming more and more apparent. This is where zircon mullite bricks come into the picture, bringing new hope and solutions to the glass industry.

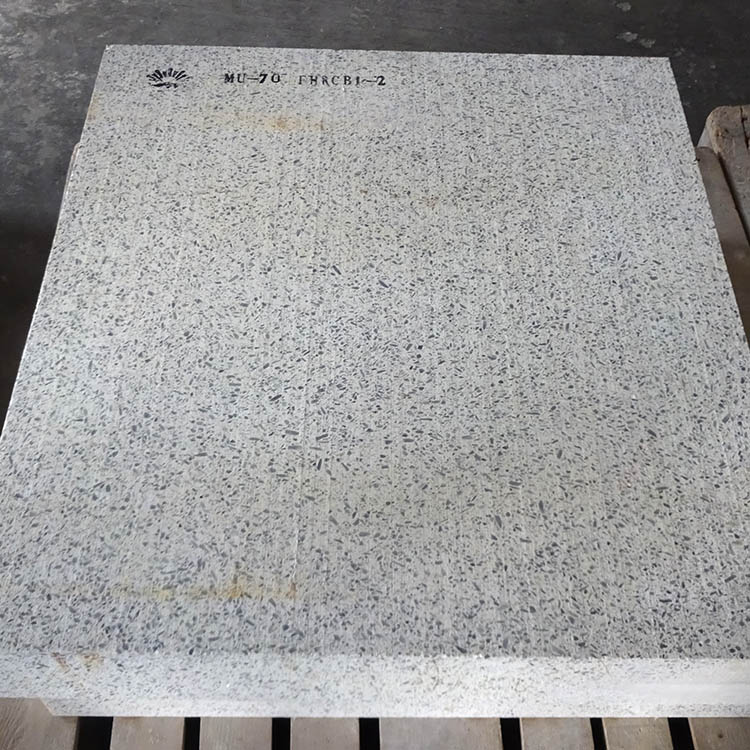

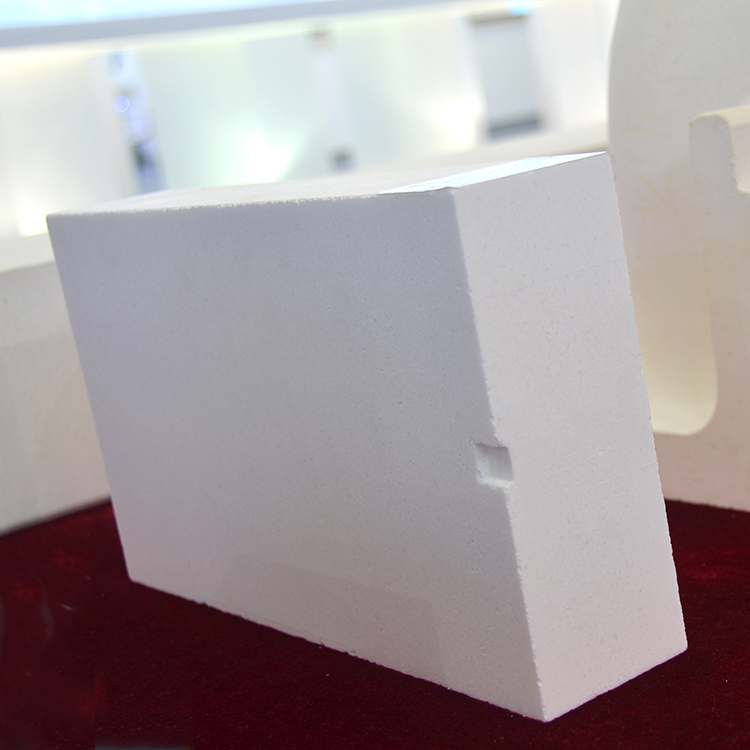

Zircon mullite bricks are made from fused zircon mullite and sintered alumina through high - temperature sintering processes. This unique manufacturing method endows them with high density and purity. In fact, they contain over 70% corundum phase. This high - corundum content is the key to their excellent performance.

Let's take a detailed look at how zircon mullite bricks outperform traditional refractory materials. In terms of thermal shock stability, traditional materials often crack or break under rapid temperature changes. However, zircon mullite bricks can withstand more than 50 thermal shock cycles without significant damage, while traditional materials may only endure 10 - 15 cycles on average. This means less downtime for equipment maintenance and replacement, greatly improving production efficiency.

When it comes to spalling resistance, zircon mullite bricks also shine. Their dense structure and high - quality raw materials make them highly resistant to spalling. In contrast, traditional refractory materials may experience spalling after just a few months of use, which not only affects the quality of glass products but also requires frequent replacement, increasing costs.

In the aspect of corrosion resistance, glass melt and various chemical substances in the production process can corrode refractory materials. Zircon mullite bricks have a much slower corrosion rate compared to traditional materials. Tests show that the corrosion rate of zircon mullite bricks is only about 30% of that of traditional refractory materials, which significantly extends the service life of the refractory lining in glass furnaces.

Many glass manufacturers around the world have already benefited from using zircon mullite bricks. A large - scale glass factory in Europe replaced its traditional refractory materials with zircon mullite bricks. After the replacement, their production efficiency increased by 20%, and the cost of refractory material replacement was reduced by 30% within a year. Another glass company in Asia reported a significant improvement in the quality of their glass products after switching to zircon mullite bricks, as the reduced spalling and corrosion ensured a more stable production environment.

In conclusion, zircon mullite bricks are a game - changer in the glass industry. They offer unparalleled advantages in thermal shock stability, spalling resistance, and corrosion resistance, which directly translate into higher production efficiency and lower costs for glass manufacturers. If you're still using traditional refractory materials, it's time to make a switch.

Contact us today to learn more about how zircon mullite bricks can transform your glass manufacturing process and bring you significant economic benefits.