Glass manufacturers worldwide face persistent challenges such as frequent furnace maintenance, high energy consumption, and inconsistent glass quality. These issues emphasize the urgent need for advanced refractory materials that can withstand the rigors of glass production. Premium silica bricks, engineered with high-purity SiO₂ content and specialized microstructures, have emerged as a game-changer. This article explores the technical foundations of these bricks, their application benefits, and real-world results that validate their role in driving efficiency and product excellence in the glass industry.

Glass furnaces typically operate under extreme thermal and chemical stress. Conventional refractory bricks frequently cause bottlenecks due to:

These pain points not only impact operational costs but also compromise final glass product quality and yield.

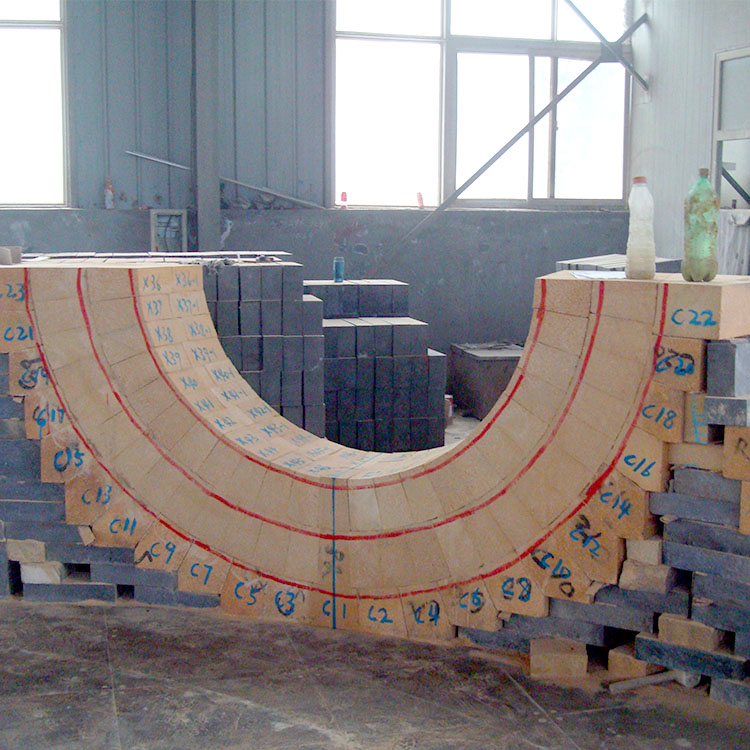

Premium silica bricks are manufactured with >96% pure silicon dioxide, leveraging the stable crystalline forms of quartz—primarily quartz and cristobalite. This composition underpins superior thermal stability at temperatures exceeding 1650°C, reducing volumetric changes that typically lead to warping or cracking.

The bricks' microstructure is optimized to exhibit:

When integrated into glass furnaces, these silica bricks deliver tangible operational advantages:

| Indicator | Traditional Refractory Bricks | Premium High-Purity Silica Bricks |

|---|---|---|

| Furnace Maintenance Interval | 3 months | 6+ months (100% increase) |

| Energy Consumption Reduction | Baseline | 8% decrease in kWh/ton glass |

| Glass Contamination Instances | Frequent | Rare / Negligible |

| Brick Density | ~2.5 g/cm³ | ~2.2 g/cm³ (10% weight reduction) |

One major European glass producer reported a doubling of repair intervals after upgrading to premium silica bricks. Their furnace maintenance cycles extended from roughly 3 to 6 months, reducing downtime by 50%. Concurrently, they achieved an 8% reduction in energy consumption per production ton, resulting in significant cost savings.

In another case, a manufacturer in North America noted fewer glass defects attributable to refractory erosion, affirming the superior chemical inertness of these bricks in their high-throughput operations.

If you are grappling with frequent furnace shutdowns or rising glass defect rates, investing in premium silica bricks could be the technology breakthrough your operation needs. By maintaining dimensional stability, resisting corrosive environments, and minimizing contamination risks, these bricks effectively lower operational risks and improve product consistency.

As the glass industry continually seeks higher productivity and sustainability, adopting these advanced refractory materials represents a strategic leverage point to outpace competitors.

The crystalline phases of quartz and cristobalite within silica bricks transform at distinct temperature thresholds, influencing their thermal expansion behavior. Carefully controlling these phases during manufacturing reduces internal stresses. Additionally, the low porosity and optimized grain boundaries contribute to exceptional corrosion resistance and lower bulk density.