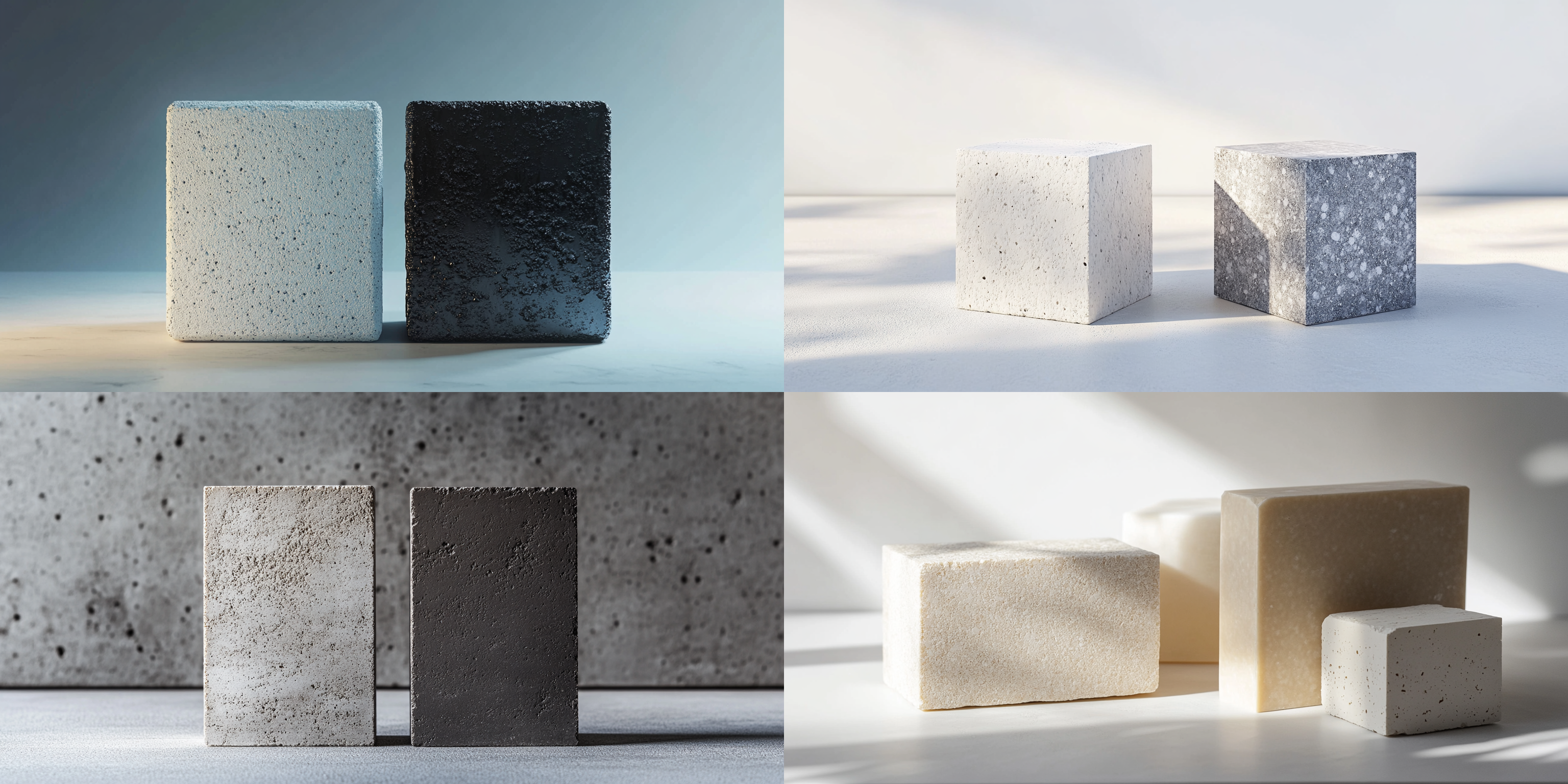

As the global glass manufacturing industry continues to evolve, manufacturers are increasingly focused on optimizing production efficiency and reducing equipment downtime. Traditional refractory materials often struggle to meet the demands of high-temperature environments, leading to frequent maintenance, reduced output, and higher operational costs. In response, sillimanite special-shaped bricks have emerged as a game-changing solution, offering exceptional thermal shock resistance, corrosion resistance, and tailored design flexibility.

Sillimanite refractory bricks are renowned for their outstanding performance in extreme conditions. These bricks exhibit:

Sillimanite special-shaped bricks are specifically engineered to fit complex geometries in key production units. Common applications include:

| Equipment Component | Application Area |

|---|---|

| Feeding System | Protects against molten glass erosion and ensures smooth material flow. |

| Pulling Machine | Withstands high temperatures and mechanical stress during glass drawing processes. |

| Melting Tank Linings | Extends service life and reduces maintenance frequency. |

.jpg)

A leading glass manufacturer in Southeast Asia reported significant improvements after replacing conventional refractories with sillimanite special-shaped bricks in its feeding system. The results included:

Another case involved a European glass producer that implemented these bricks in its pulling machine. Over six months, the facility observed a 40% extension in brick lifespan, directly contributing to stable operations and cost savings.

.jpg)

For glass industry professionals evaluating refractory solutions, sillimanite special-shaped bricks offer a compelling value proposition:

These benefits make sillimanite special-shaped bricks an essential choice for manufacturers aiming to achieve sustainable growth and competitive advantage in a demanding market.

Ready to transform your glass production process? Explore how our advanced refractory solutions can help you boost productivity, reduce risks, and ensure stable operations.

Get Your Free Product Evaluation Report Now