.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

The global refractory materials market has witnessed significant growth in recent years, driven by the expansion of industries such as steel, cement, and glass. According to market research, the global refractory materials market size was valued at approximately $25 billion in 2023 and is expected to grow at a CAGR of 3.5% from 2024 to 2030. As these industries continue to evolve, there is an increasing demand for high - performance refractory materials that can withstand extreme temperatures, chemical corrosion, and mechanical stress. This is where directly bonded magnesia - chrome bricks come into play.

Traditional magnesia - chrome bricks, such as unfired magnesia - chrome bricks, have been widely used in the past. The production process of unfired magnesia - chrome bricks typically involves mixing magnesia and chrome ore powders with a binder, followed by pressing and curing. These bricks offer certain advantages, including relatively low cost and good initial corrosion resistance. However, they also have significant limitations. For example, unfired magnesia - chrome bricks have relatively low strength at high temperatures, with a compressive strength of around 30 - 40 MPa at 1400°C. They are also more prone to cracking and spalling under thermal cycling conditions, which can reduce their service life and performance.

.jpg)

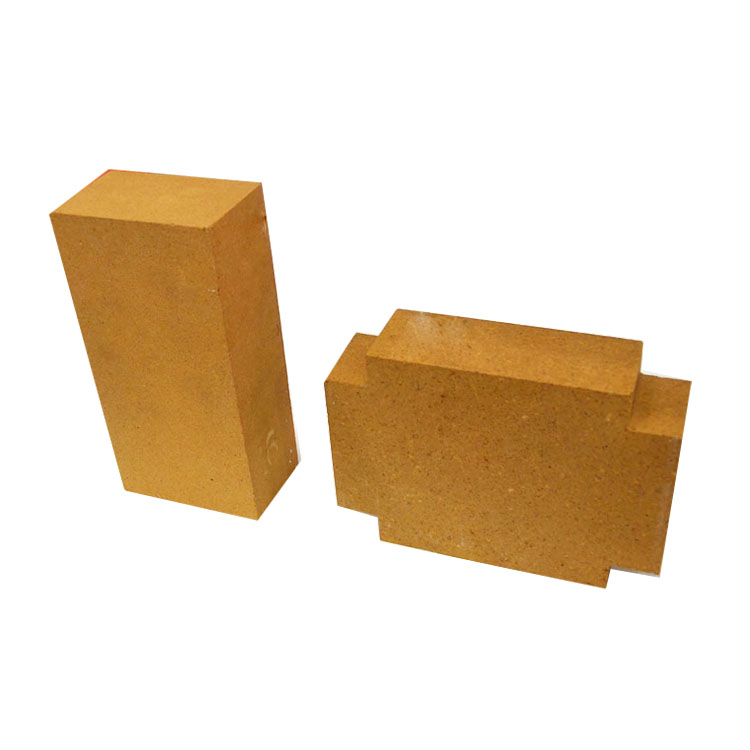

Directly bonded magnesia - chrome bricks are produced through a high - temperature sintering process, which forms a direct bond between the magnesia and chrome phases. This results in several outstanding properties. Firstly, they have excellent high - temperature strength, with a compressive strength of up to 60 - 80 MPa at 1400°C, which is significantly higher than that of traditional magnesia - chrome bricks. Secondly, they exhibit superior thermal shock resistance, able to withstand rapid temperature changes without significant damage. Thirdly, their corrosion resistance is also remarkable, especially against slag and molten metals. These properties make directly bonded magnesia - chrome bricks well - suited to meet the demanding requirements of modern industries, effectively addressing the limitations of traditional products.

.jpg)

Directly bonded magnesia - chrome bricks have had a profound impact on the refractory materials industry. In terms of technological upgrading, they have spurred the development of new production techniques and quality control methods. This has led to an overall improvement in the quality and performance of refractory products. In the market, they have gradually replaced traditional magnesia - chrome bricks in high - end applications, changing the market landscape. The market share of directly bonded magnesia - chrome bricks has increased from 20% in 2020 to approximately 35% in 2024, indicating a growing preference among customers.

One overseas steel plant replaced its traditional magnesia - chrome bricks with directly bonded magnesia - chrome bricks in its steel - making furnace. As a result, the service life of the furnace lining increased from 6 months to 10 months, reducing maintenance costs by 30%. A customer from this plant commented, "The directly bonded magnesia - chrome bricks have truly exceeded our expectations. Their performance has significantly improved the efficiency of our production process." Another glass manufacturing company also reported similar positive experiences after using directly bonded magnesia - chrome bricks, with reduced downtime and improved product quality.

Looking ahead, the future of directly bonded magnesia - chrome bricks is bright. With the continuous development of industries and the increasing focus on environmental protection and energy efficiency, there will be even higher requirements for refractory materials. Directly bonded magnesia - chrome bricks, with their excellent performance, are well - positioned to lead the industry towards a more high - performance and high - quality future. Additionally, government policies that support the development of advanced manufacturing are also expected to provide favorable conditions for the growth of this product.

Don't miss out on the opportunity to enhance your production efficiency and reduce costs with our high - quality directly bonded magnesia - chrome bricks. Contact us today to learn more about our products and how they can benefit your business!