.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

The global refractory material market is experiencing significant growth, driven by increasing demand from industries such as steel, cement, and glass. As these industries continue to expand and modernize, the need for high - performance refractory materials has become more pressing. In this context, direct - bonded magnesia - chrome bricks have emerged as a game - changer, offering new opportunities for the refractory material market.

.jpg)

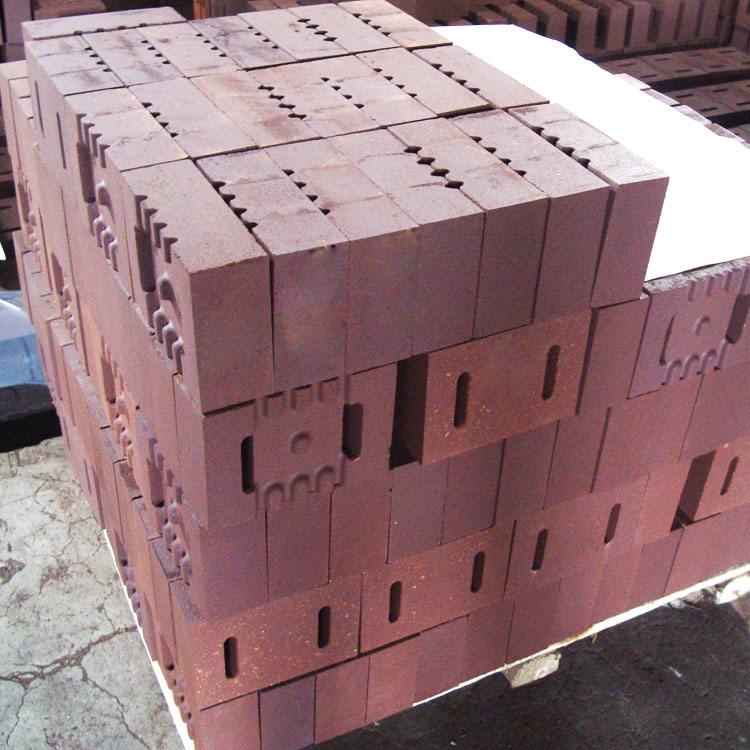

Traditional magnesia - chrome bricks come in various types. Some are produced by utilizing the reaction between iron oxide and spinel, while others are made from synthetic co - fired materials. There are also unburned magnesia - chrome bricks, which have a simple production process, low cost, and good thermal stability. However, their high - temperature strength is far inferior to that of burned bricks. For example, unburned bricks may only withstand temperatures up to 1300°C, while burned magnesia - chrome bricks can handle temperatures up to 1600°C.

.jpg)

Direct - bonded magnesia - chrome bricks, as a new product, have excellent performance. They have a high melting point, typically above 1800°C, which makes them suitable for use in extremely high - temperature environments. Their chemical stability is also remarkable, as they can resist the corrosion of various slags and gases. In addition, these bricks have high mechanical strength, which means they can maintain their shape and integrity under heavy loads.

The introduction of direct - bonded magnesia - chrome bricks has brought new vitality to the refractory material market. It is estimated that the global demand for high - performance refractory materials, including direct - bonded magnesia - chrome bricks, will grow at an annual rate of 5% in the next five years. These bricks are gradually replacing traditional magnesia - chrome bricks in many high - end applications, such as steelmaking and cement production.

Many well - known companies in the steel and cement industries have adopted direct - bonded magnesia - chrome bricks. For example, a large steel mill in Europe reported that after using these bricks, the service life of their furnaces increased by 30%, reducing maintenance costs and production interruptions. Another cement plant in Asia found that the energy consumption of their kilns decreased by 15% due to the excellent thermal insulation performance of direct - bonded magnesia - chrome bricks.

The future of direct - bonded magnesia - chrome bricks looks promising. With the continuous development of high - temperature industries, the demand for high - performance refractory materials will only increase. Direct - bonded magnesia - chrome bricks, with their superior performance, are expected to play an even more important role in the global refractory material market.

Don't miss out on the new opportunities in the refractory material market! Direct - bonded magnesia - chrome bricks are your key to high - performance and cost - effective solutions. Contact us today to learn more and place your order!