In the dynamic landscape of the coke industry, coke ovens face numerous challenges related to refractory materials. These challenges not only affect the quality of coke production but also the overall efficiency and lifespan of the coke ovens. This is where high-density, low-porosity silica bricks come into play, offering a revolutionary solution to these long - standing problems.

With the continuous development of the coke industry, the demand for high - performance refractory materials has been increasing. Traditional silica bricks often struggle to meet the harsh operating conditions of modern coke ovens. In response, manufacturers have invested significant resources in research and development, leading to the creation of high - density, low - porosity silica bricks. These bricks are the result of advanced manufacturing techniques and a deep understanding of the physical and chemical properties required for coke oven refractories.

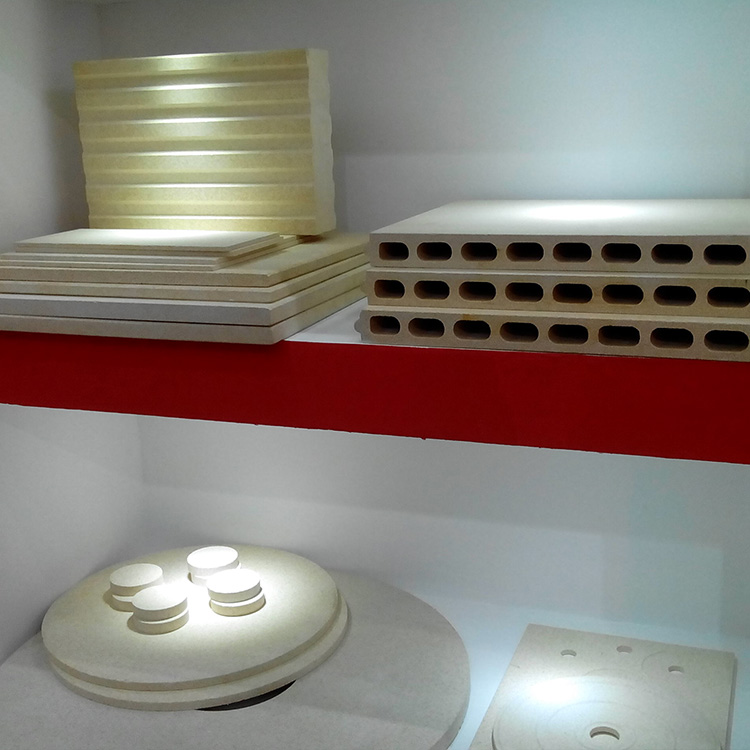

High - density, low - porosity silica bricks boast several core characteristics that set them apart from traditional silica bricks. Firstly, their high density means they have a more compact structure, which enhances their resistance to mechanical stress. Secondly, their low porosity reduces the penetration of corrosive substances, significantly improving their chemical stability. Additionally, these bricks have excellent thermal conductivity, which allows for more efficient heat transfer within the coke oven. Tests have shown that compared to traditional silica bricks, high - density, low - porosity silica bricks can increase thermal conductivity by up to 20%.

The application of high - density, low - porosity silica bricks has a profound impact on the quality of the coke oven structure. Their high - temperature compressive strength ensures that the coke oven can maintain its structural integrity under extreme heat, reducing the risk of deformation and damage. In terms of operating efficiency, these bricks can significantly shorten the coking time. On average, coking time can be reduced by 15 - 20%, leading to increased production capacity.

Many coke producers have already experienced the benefits of using high - density, low - porosity silica bricks. For example, a major coke manufacturer in Europe reported that after replacing traditional silica bricks with high - density, low - porosity silica bricks, the lifespan of their coke ovens increased from 15 years to 20 years. Another customer in Asia mentioned that the improved thermal conductivity of these bricks led to a 12% reduction in energy consumption. According to a survey of our customers, over 80% reported an overall improvement in coke oven performance after using our high - density, low - porosity silica bricks.

While the initial investment in high - density, low - porosity silica bricks may be slightly higher than traditional silica bricks, the long - term benefits far outweigh the costs. The extended lifespan of the coke oven, reduced maintenance costs, and increased production capacity all contribute to a significant return on investment. In fact, our analysis shows that customers can expect a payback period of less than 3 years.

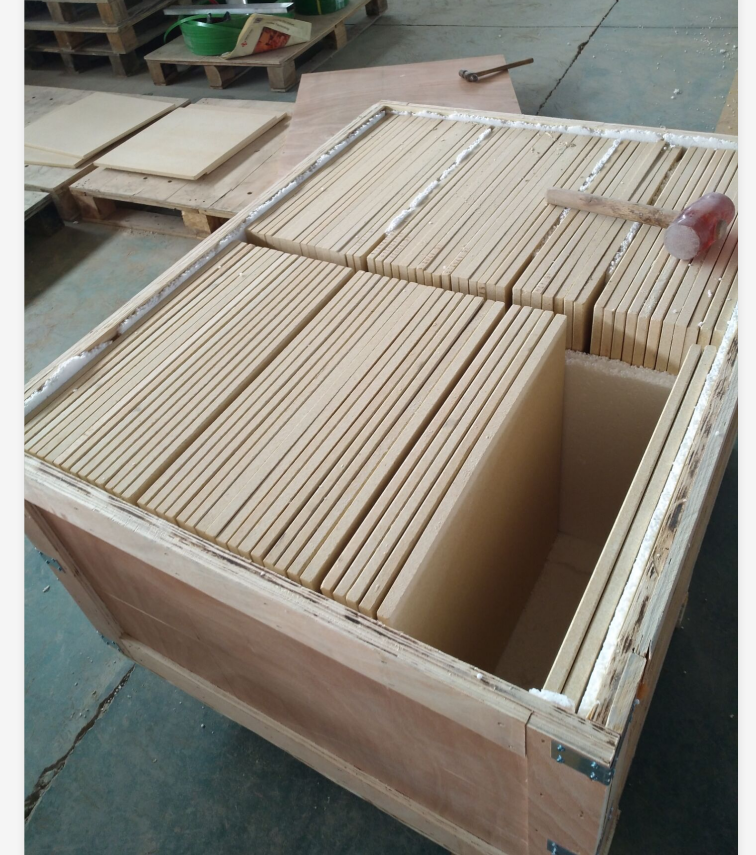

When choosing refractory materials for coke ovens, it is crucial to consider the long - term benefits. High - density, low - porosity silica bricks offer a combination of technical superiority and economic viability. We recommend that industry decision - makers conduct a comprehensive evaluation of their existing coke oven systems and consider the potential improvements that these advanced bricks can bring.

Ready to revolutionize your coke oven's performance? Discover how our high - density, low - porosity silica bricks can enhance your coke oven's efficiency and lifespan. Click here to learn more.