In the global glass manufacturing industry, the persistent issue of glass liquid pollution has been a longstanding headache. Contaminants in the glass liquid can cause various defects, such as bubbles and visible inclusions, seriously affecting the quality and efficiency of glass production. These problems not only increase production costs but also impact the competitiveness of glass products in the market.

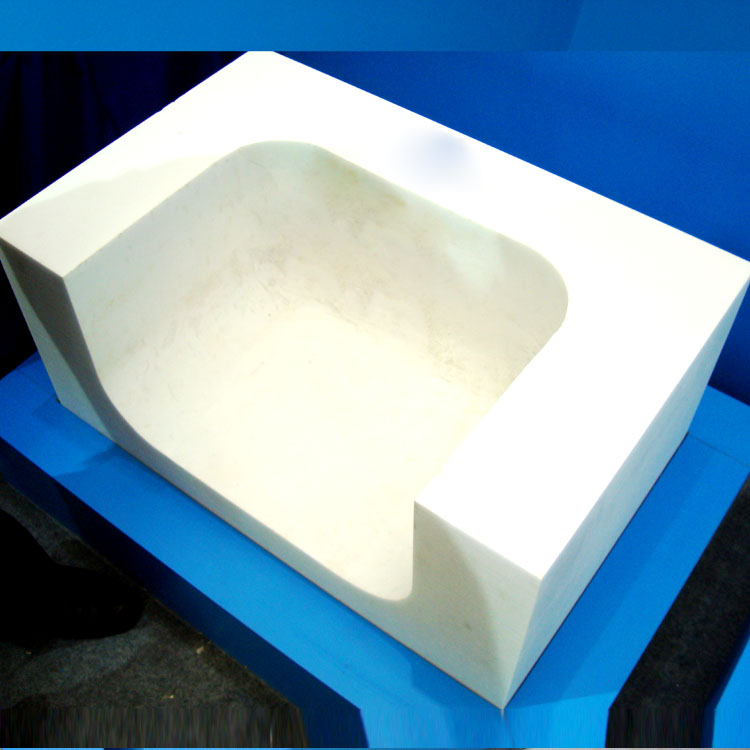

Enter the high-purity fused α-alumina block TY-A, a game - changer in the glass production industry. This product is made from high-purity raw materials with an Al₂O₃ content of ≥98%. What sets it apart even more is the absence of Fe₂O₃ and TiO₂ impurities. These two impurities are common culprits in glass liquid pollution.

In traditional glass production, Fe₂O₃ and TiO₂ can react with other components in the glass, leading to the formation of bubbles and colored inclusions in the glass. For high - quality glass products, even the slightest impurity can be unacceptable. The TY-A high-purity fused α-alumina block completely eliminates these concerns. Factories using TY-A have reported a significant reduction in the number of bubbles in the glass liquid, up to a 70% decrease in some cases. This directly translates into fewer defective products and a higher overall quality of glass production.

The 2000°C electric furnace melting process used in the production of TY-A is another key factor contributing to its excellent performance. This high - temperature melting process forms a dense structure in the alumina block. The dense structure gives TY-A outstanding alkali resistance and high - temperature stability.

In the glass production environment, the glass liquid often contains alkaline substances, which can corrode the refractory materials. The excellent alkali resistance of TY-A ensures that it can withstand long - term contact with the alkaline glass liquid without significant corrosion. Moreover, it can maintain its structural integrity at temperatures as high as 1350°C, providing a stable environment for glass melting. This high - temperature stability is crucial for reducing energy consumption in the glass melting process. Enterprises using TY-A have recorded an average energy consumption reduction of about 15% compared with traditional refractory materials.

Case 1: A large - scale glass manufacturer in Europe

After switching to the TY-A high - purity fused α-alumina block, they experienced a 60% decrease in the glass product defect rate within six months. The improved glass quality also allowed them to increase the selling price of their products by about 10% in the market.

Case 2: An Asian glass factory

The use of TY-A led to a 20% increase in production line efficiency. The reduced maintenance frequency of refractory materials due to its excellent corrosion resistance also saved a significant amount of production time and cost.

The high - purity fused α-alumina block TY-A offers multiple benefits for glass manufacturers. It effectively reduces glass liquid pollution, thereby improving the quality of glass products. The excellent alkali resistance and high - temperature stability enhance production efficiency, reduce energy consumption, and lower the defect rate. If you are looking to upgrade your glass production line, enhance product quality, and increase production efficiency, the TY-A high - purity fused α-alumina block is the ideal choice.