In the glass production process, glass melt contamination is a significant issue that seriously affects product quality and production efficiency. High-purity fused α-alumina blocks TY-A offer an effective solution to this problem.

The high-purity fused α-alumina blocks TY-A are manufactured using high-purity alumina raw materials with an Al2O3 content of over 98%. This high purity is crucial as it avoids the problems caused by impurities such as Fe2O3 and TiO2. In traditional glass production, these impurities can lead to the formation of bubbles in the glass melt. For example, in a glass factory, when using materials with a relatively high content of these impurities, the bubble defect rate in the final glass products could reach up to 15%. However, after switching to the high-purity fused α-alumina blocks TY-A, the bubble defect rate dropped to less than 3%.

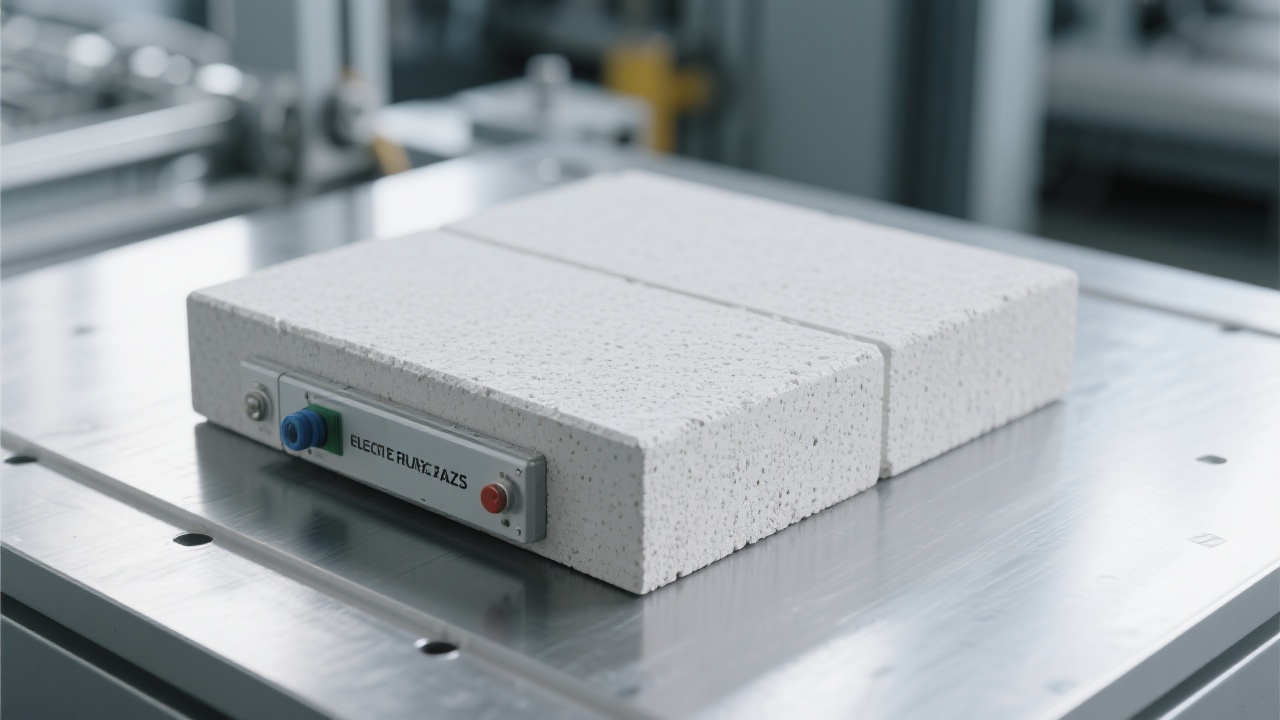

The blocks are formed through a melting-casting process in an electric furnace at 2000℃. This high - temperature process results in a dense structure, which endows the products with excellent resistance to strong alkalis and corrosion resistance at a high temperature of 1350℃. In a long - term glass melting environment, materials without such performance may degrade rapidly, increasing the risk of glass melt contamination. Research shows that compared with ordinary refractory materials, the service life of high-purity fused α-alumina blocks TY-A in the glass melting furnace is extended by about 50%, from an average of 2 years to 3 years.

Let's take a real glass production enterprise as an example. Before using the high-purity fused α-alumina blocks TY-A, the glass melt purity was relatively low, and the quality of glass products was unstable. The production efficiency was also affected by frequent equipment maintenance due to material corrosion. After the application of TY - A blocks, within a year, the purity of the glass melt increased by 20%, and the production efficiency improved by 15% as the equipment maintenance frequency decreased significantly. The quality of the final glass products also improved, with the proportion of high - grade products rising from 60% to 80%.

These data clearly demonstrate the significant advantages of high-purity fused α-alumina blocks TY-A in reducing glass melt contamination and improving product quality and production efficiency. For glass production enterprises, choosing this product can provide strong technical support to enhance their market competitiveness. Don't miss this opportunity to improve your glass production process!

Click here to Try High - Purity Fused α - Alumina Blocks TY - A Now!