In the metallurgical industry, the procurement of mullite bricks often poses a significant challenge for decision - makers. Mullite bricks are crucial refractory materials widely used in high - temperature environments, playing a vital role in ensuring the stable operation of metallurgical furnaces and other equipment. Selecting the right mullite bricks can enhance production efficiency, reduce maintenance costs, and extend the service life of equipment.

Sintered mullite bricks are typically made from high - alumina bauxite, kaolin, and other raw materials. The production process involves batching, mixing, forming, and high - temperature sintering. During sintering, the raw materials undergo a series of physical and chemical reactions, forming a stable crystal structure. Sintered mullite bricks are known for their high strength, good thermal shock resistance, and excellent chemical stability. According to industry data, sintered mullite bricks can withstand temperatures up to 1700°C and have a compressive strength of about 50 - 100 MPa.

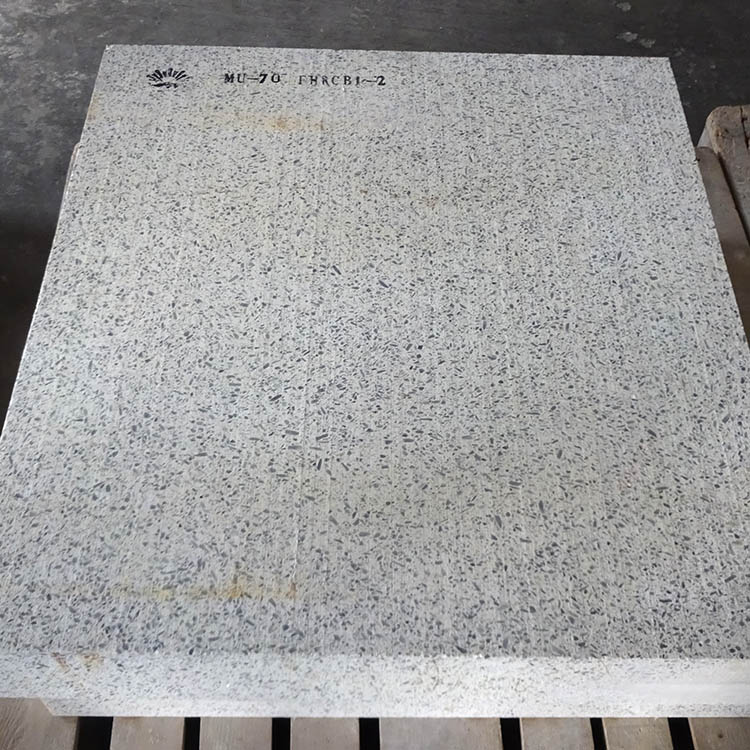

Fused mullite bricks are produced by melting high - purity alumina and silica raw materials in an electric arc furnace at extremely high temperatures and then casting and cooling them. This process results in a dense and homogeneous structure. Fused mullite bricks have superior refractoriness, withstanding temperatures up to 1800°C. They also have excellent corrosion resistance, making them suitable for harsh chemical environments. Industry statistics show that fused mullite bricks have a higher thermal conductivity compared to sintered mullite bricks, which can reach about 3 - 5 W/(m·K).

| Aspect | Sintered Mullite Bricks | Fused Mullite Bricks |

|---|---|---|

| Composition | High - alumina bauxite, kaolin | High - purity alumina and silica |

| Manufacturing Process | Batching, mixing, forming, sintering | Melting in an electric arc furnace, casting, cooling |

| Performance | Good thermal shock resistance, high strength | Superior refractoriness, excellent corrosion resistance |

In the metallurgical industry, sintered mullite bricks are commonly used in the lining of blast furnaces, hot - blast stoves, and other equipment where good thermal shock resistance is required. Fused mullite bricks, on the other hand, are often used in the lining of electric arc furnaces, ladles, and other parts exposed to extremely high temperatures and harsh chemical environments. In the ceramic industry, both types of mullite bricks can be used in kilns for firing ceramics.

In summary, sintered mullite bricks offer good thermal shock resistance and high strength, while fused mullite bricks provide superior refractoriness and corrosion resistance. The choice between them depends on specific application requirements, such as temperature, chemical environment, and mechanical stress. Our company specializes in producing high - quality mullite bricks. We have strict quality control measures throughout the production process, ensuring that our products meet the highest industry standards. Whether you need sintered or fused mullite bricks, we can provide you with the most suitable solutions.

Contact us now to discuss your mullite brick needs and let us help you make the best choice for your business!