Are you struggling to maintain consistent temperature distribution in your hot blast stoves? If so, you're not alone—many steel producers face inefficiencies due to uneven heat transfer, leading to increased energy consumption and inconsistent product quality.

Enter high-conductivity silicon brick—a proven solution that leverages its unique flaky quartz microstructure to enhance thermal conductivity by up to 40% compared to traditional fireclay bricks. This isn't just theory—it’s backed by real-world performance data from plants across Asia and Europe.

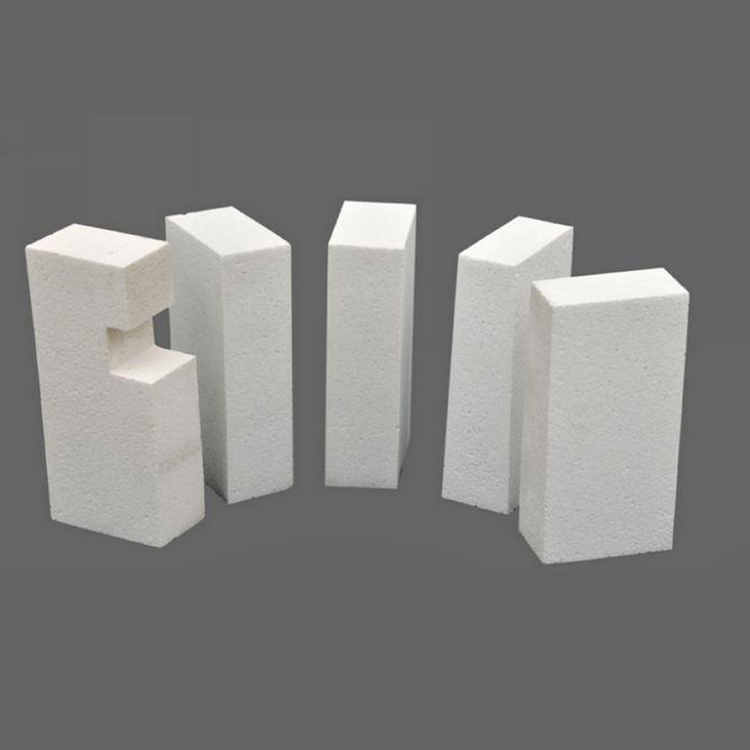

Unlike conventional refractory materials, silicon brick contains over 85% flaky quartz crystals, which act as natural heat conduits. These aligned structures allow for rapid, uniform heat propagation throughout the hot blast stove lining—reducing hot spots and cold zones that compromise furnace stability.

| Refractory Type | Thermal Conductivity (W/m·K) | Avg. Energy Savings |

|---|---|---|

| Standard Fireclay | 1.2–1.5 | ~8% |

| High-Conductivity Silicon Brick | 2.0–2.5 | ~18%* |

*Based on case studies from Chinese steel mills using silicon brick in hot blast stoves since 2021. Actual savings vary by operating conditions.

A major steel producer in India reported a 17.3% reduction in gas consumption after replacing standard bricks with high-conductivity silicon brick in two of their three hot blast stoves. They also noted improved consistency in iron quality—specifically, a 12% decrease in sulfur content due to more stable combustion temperatures.

And it’s not just about efficiency. The installation process is simplified thanks to fewer joints and better dimensional accuracy—cutting downtime by an average of 2–3 days per unit. Maintenance intervals have extended from every 6 months to over 12 months, reducing labor costs significantly.

Whether you’re managing a small-scale operation or a large integrated plant, optimizing your hot blast system doesn’t have to be complex. With silicon brick, you get smarter heat management—not just higher temps, but smarter use of every degree.

You may already know the pain points: inconsistent output, rising fuel bills, and unpredictable maintenance cycles. But what if there was a way to turn those challenges into competitive advantages?

Ready to unlock the full potential of your hot blast system? Let’s explore how our high-conductivity silicon brick can help you reduce waste, improve yield, and build long-term operational resilience.

Start Your Efficiency Transformation Today