In the aluminum industry, energy efficiency isn’t just a goal—it’s a survival imperative. With global electricity costs rising by 12% annually in high-output regions like China and the Middle East, and regulatory pressure mounting for carbon reduction, electrolytic cells must operate smarter—not harder.

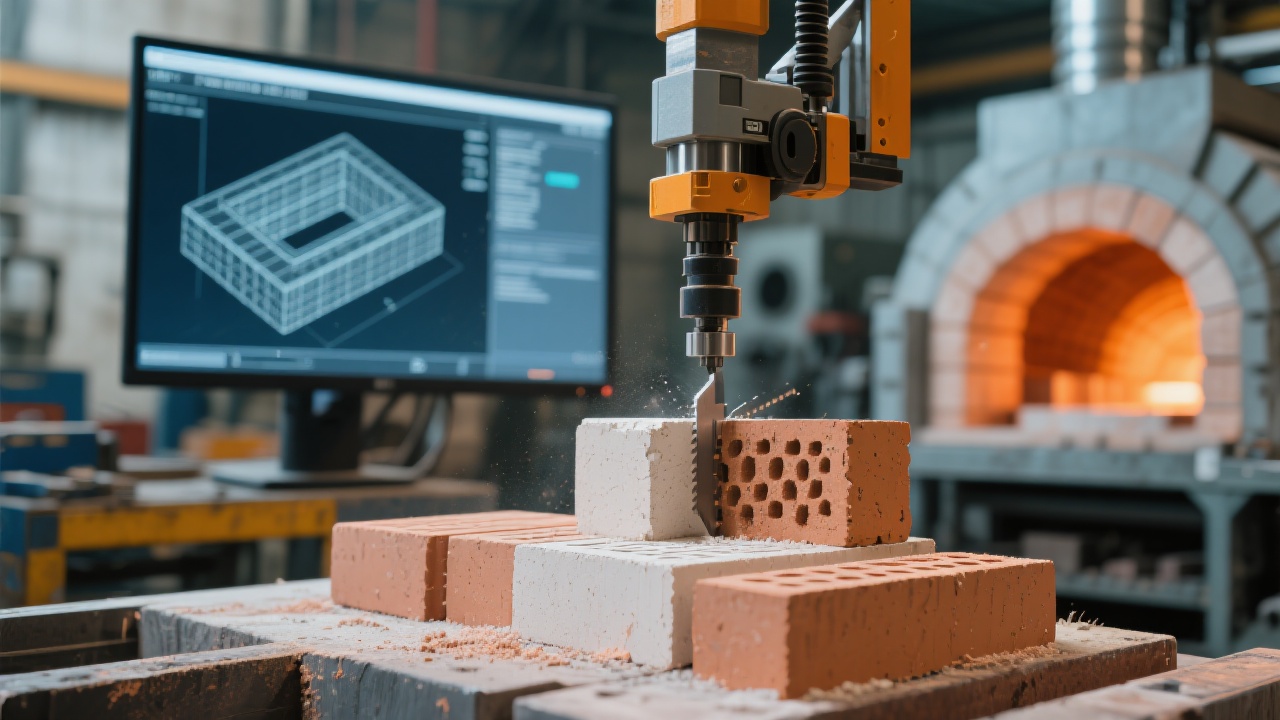

That’s where vermiculite insulation panels come in. Unlike traditional refractory bricks or mineral wool, vermiculite offers unique advantages that align perfectly with modern aluminum production demands: thermal stability, self-enhancing performance, corrosion resistance, and long-term cost savings.

According to a 2023 study by the International Aluminium Institute (IAI), inefficient insulation accounts for up to 8–12% of total electrical consumption in primary aluminum smelting. In one case from an Indian plant using outdated ceramic fiber blankets, maintenance downtime increased by 35% due to heat-induced degradation—costing over $1.2 million per year in lost output.

But here's what many procurement teams miss: insulation doesn’t just stay static—it can actually improve with use under certain conditions.

Vermiculite is a naturally occurring hydrous phyllosilicate mineral that expands when heated—up to 15x its original volume. This expansion creates micro-pores that trap air, reducing thermal conductivity over time rather than increasing it (as with some competing materials).

Real-world data from a Norwegian aluminum producer shows a 7% drop in surface temperature after 6 months of operation—a sign of improved insulation integrity. Why? The material undergoes “performance self-optimization” during initial heating cycles, forming a denser, more stable matrix.

| Feature | Traditional Insulation | Vermiculite Panel |

|---|---|---|

| Thermal Conductivity (W/m·K) | 0.06–0.12 | 0.04–0.08 (improves over time) |

| Service Life (Years) | 3–5 | 8–12+ |

| Resistance to Fluoride Corrosion | Low | High (tested at 1200°C) |

Moreover, these panels excel in resisting ice crystal and cryolite attack—an issue that plagues many smelters in colder climates. A recent field test at a Canadian facility showed zero structural damage after 18 months of continuous exposure to molten cryolite at 960°C, while conventional materials failed within 9 months.

By switching to vermiculite-based insulation, companies report average annual energy savings of 9–14%, translating to 120–180 MWh per cell per year. That’s not just green—it’s profitable. One U.S.-based aluminum recycler calculated a payback period of just 14 months on a full-cell retrofit project.

As sustainability becomes central to supply chain compliance (especially in EU and North America), choosing materials like vermiculite helps future-proof operations against evolving ESG standards.

Ready to reduce your energy footprint and boost cell longevity?

Explore how our verified vermiculite insulation solutions have helped over 40 aluminum plants across Europe, Asia, and North America achieve measurable improvements in efficiency, safety, and environmental performance.