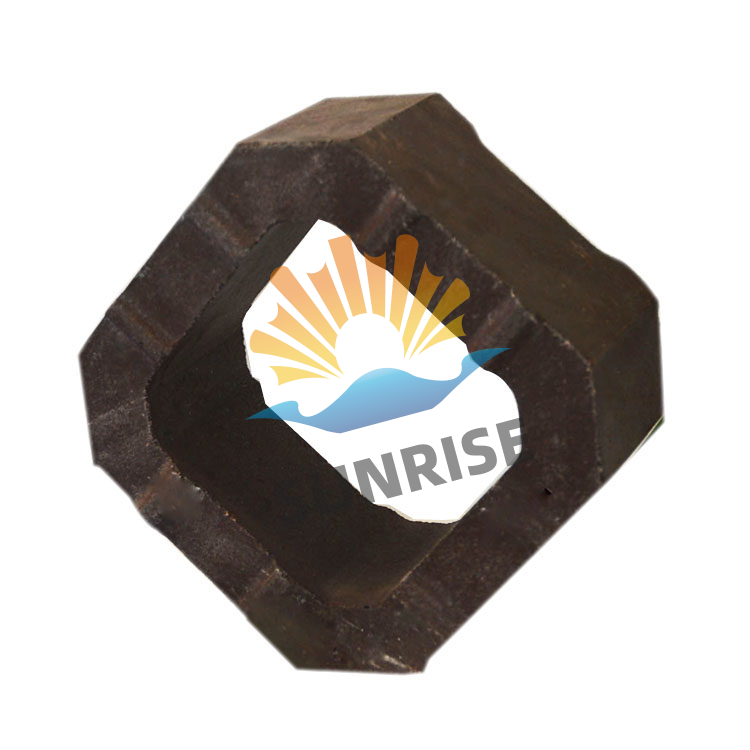

In the glass manufacturing industry, the stability and efficiency of glass furnaces are of utmost importance. High - quality silica bricks play a crucial role in ensuring the smooth operation of glass furnaces. This article will delve into the chemical composition of high - quality silica bricks and how their high SiO₂ content endows them with excellent high - temperature resistance and volume stability.

Silica bricks used in glass kilns typically have a high SiO₂ content, often exceeding 95%. This high SiO₂ content is the key to their outstanding high - temperature performance. SiO₂ has a high melting point, around 1713°C. When the silica brick is exposed to high temperatures in the glass furnace, the high - purity SiO₂ structure can maintain its integrity, preventing the brick from melting or deforming easily.

The high - temperature volume stability of silica bricks is also closely related to their chemical composition. During the heating process, the high - quality silica brick undergoes a series of phase transitions. These phase transitions are well - controlled due to the high SiO₂ content, resulting in minimal volume changes. For example, in a glass furnace operating at around 1400 - 1500°C, a high - quality silica brick with a high SiO₂ content may only experience a volume change of less than 0.5%, while ordinary refractory materials may have a volume change of up to 2 - 3%.

The high - temperature volume stability of silica bricks has a direct impact on the stable operation of glass furnaces. When the furnace is heated, if the refractory material has large volume changes, it can cause cracks and deformations in the furnace structure. These cracks can lead to heat leakage, which not only increases energy consumption but also poses a risk to the safety of the furnace. In contrast, high - quality silica bricks with excellent volume stability can effectively reduce the occurrence of such problems.

Let's look at some data. A glass production enterprise that used ordinary refractory materials in its glass furnace had to carry out major repairs every 1 - 2 years. After switching to high - quality silica bricks, the repair frequency was reduced to once every 3 - 5 years. This significant reduction in repair frequency not only saves maintenance costs but also extends the service life of the furnace.

In the furnace structure, high - quality silica bricks can reduce cracks and deformations caused by thermal expansion. The stable volume of silica bricks under high - temperature conditions means that they can better adapt to the thermal environment of the furnace. When the furnace is heated and cooled, the silica bricks can maintain a relatively stable shape, preventing the formation of large internal stresses that could lead to cracks.

For instance, in a glass furnace, the temperature difference between the inner and outer walls of the furnace can be several hundred degrees Celsius. High - quality silica bricks can withstand this large temperature difference without significant volume changes, ensuring the overall stability of the furnace structure.

Many glass production enterprises have benefited from using high - quality silica bricks. One such enterprise, XYZ Glass Co., Ltd., was facing frequent furnace breakdowns, which seriously affected its production efficiency and product quality. After replacing the original refractory materials with high - quality silica bricks, the company saw a significant improvement. The production efficiency increased by 20%, and the defect rate of glass products decreased by 15%. This not only improved the company's market competitiveness but also enhanced its profitability.

If you are troubled by furnace problems, consider using our high - quality silica bricks for glass kilns. They can help improve production efficiency and reduce failure rates. Click here to learn more about our products and how they can benefit your glass production business.