In the competitive glass manufacturing industry, maintaining a consistently high quality of glass melt is vital to producing defect-free glass products and maximizing yield rates. Impurities and gas bubbles introduced during the melting process can significantly deteriorate the final product’s clarity and physical attributes, impacting both customer satisfaction and operational efficiency. Addressing these challenges at the raw material and furnace lining level can yield transformative benefits.

Glass melt purity is often compromised by unwanted inclusions and chemical contaminants originating from refractory materials used in the furnace lining. These contaminants, particularly iron oxide (Fe₂O₃) and titanium dioxide (TiO₂), catalyze gas bubble formation, create nucleation sites for defects, and lead to lower glass transparency. The industry benchmark demands material solutions with minimal impurity levels to ensure the molten glass remains clean and structurally sound throughout the high-temperature melting process.

“Empirical trials have shown a 35% reduction in bubble defects and a 25% improvement in glass clarity when high-purity fused α-alumina blocks replace conventional refractory materials.” — Industry Data Report, 2023

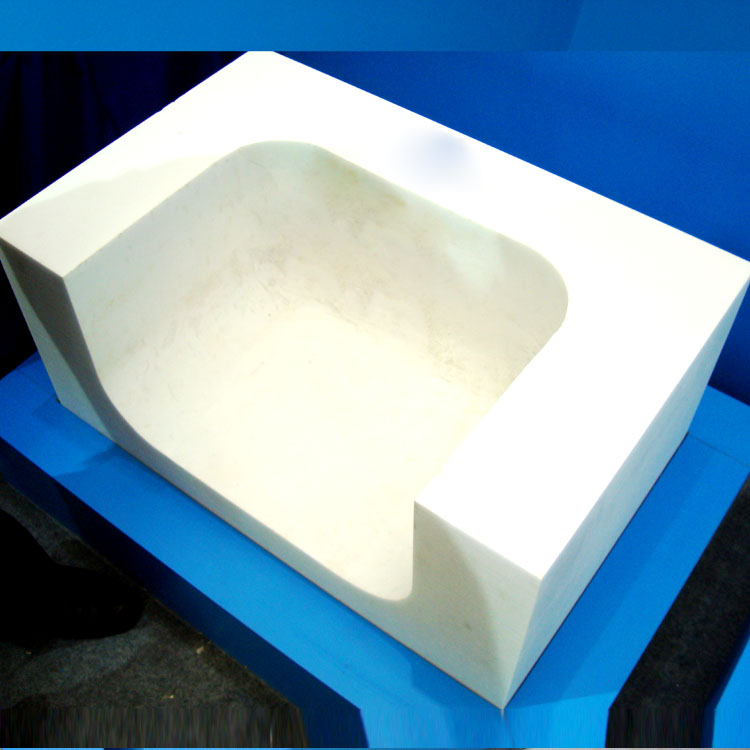

The TY-A high purity fused α-alumina block stands out due to its exceptional chemical and physical properties optimized for glass furnace applications:

The TY-A block’s performance roots in its meticulous chemical composition and refined manufacturing process. The absence of Fe₂O₃ and TiO₂ mitigates catalytic reactions which typically generate micro-bubbles within the melt. Dense microstructuring limits the permeability of molten glass and volatile compounds, preventing refractory degradation and secondary contamination.

Furthermore, the α-phase alumina crystal structure formed at 2000℃ imparts exceptional mechanical strength and chemical resistance, crucial for withstanding the cyclic thermal stresses and aggressive environments inside glass kilns.

Multiple glass manufacturers who transitioned to TY-A fused α-alumina blocks report quantifiable improvements:

| Metric | Before TY-A | After TY-A Installation | Improvement (%) |

|---|---|---|---|

| Bubble Count per m³ | 1500 | 975 | 35.0% |

| Glass Defect Rate | 4.2% | 3.15% | 25.0% |

| Kiln Downtime due to Lining Repair | 12 days/year | 7 days/year | 41.7% |

These figures underscore TY-A’s contribution not only to product quality enhancement but also to operational cost savings through reduced downtime and scrap rates. The enhanced durability extends refractory service life, increasing overall furnace efficiency.

Integrating TY-A fused α-alumina blocks into the refractory lining system translates into sustained purity of molten glass, driving higher product consistency. It empowers manufacturers to meet stringent quality certifications and customer specifications — a decisive advantage in global marketplaces.

Moreover, operational reliability is enhanced by the refractory’s resistance to chemical corrosion and mechanical wear under harsh kiln environments, reducing maintenance frequency and associated production losses.

Choose TY-A = Choose Pure Glass Melt

Unlock superior glass quality and efficiency for your production line today.