In the realm of refractory materials, global buyers often find themselves at a crossroads when selecting the most suitable option for their specific industrial needs. Mullite bricks, known for their exceptional refractory properties, have emerged as a popular choice across various industries. However, understanding the different types of mullite bricks and their unique characteristics is crucial for making an informed purchasing decision.

There are two main types of mullite bricks: sintered mullite bricks and fused mullite bricks. Each type has its own distinct raw materials, manufacturing processes, and performance characteristics.

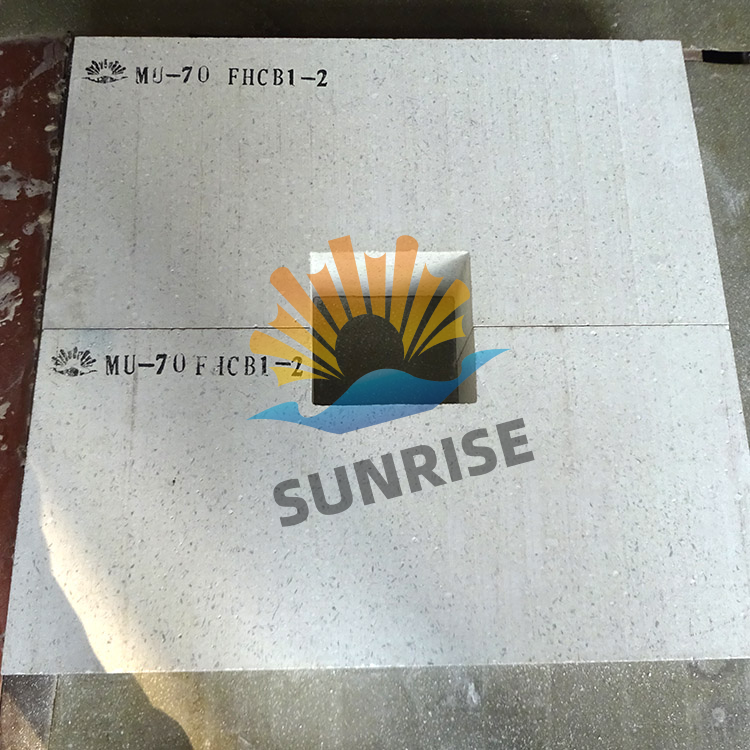

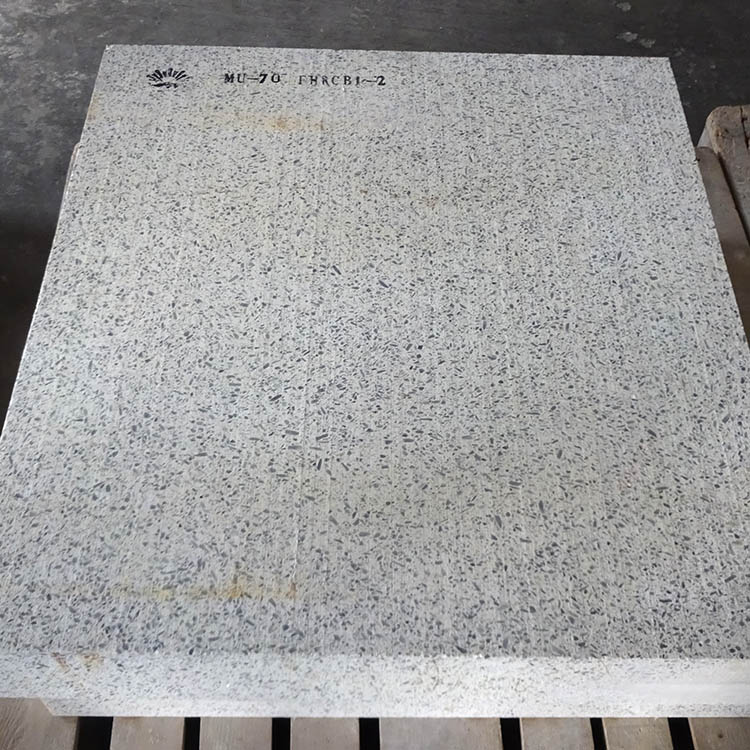

Sintered mullite bricks are typically made from high - alumina bauxite, kaolin, and other alumina - rich raw materials. The manufacturing process involves mixing the raw materials, forming them into brick shapes, and then sintering them at high temperatures (usually around 1600 - 1700°C). This process results in a brick with a dense structure and good thermal stability. Sintered mullite bricks have a relatively high alumina content, often ranging from 70% - 85%, which gives them excellent resistance to corrosion and thermal shock.

Fused mullite bricks are produced by melting high - purity alumina and silica raw materials in an electric arc furnace at extremely high temperatures (above 2000°C). The molten material is then cast into molds and cooled to form bricks. Fused mullite bricks have a more uniform crystal structure and higher purity compared to sintered mullite bricks. They offer superior mechanical strength, thermal conductivity, and resistance to chemical attack. The alumina content in fused mullite bricks can be as high as 90% - 95%.

Let's take a closer look at the differences between sintered and fused mullite bricks in terms of composition, manufacturing method, and performance:

| Aspect | Sintered Mullite Bricks | Fused Mullite Bricks |

|---|---|---|

| Composition | 70% - 85% alumina | 90% - 95% alumina |

| Manufacturing Method | Sintering at 1600 - 1700°C | Melting in an electric arc furnace above 2000°C |

| Performance | Good thermal stability, corrosion resistance | Superior mechanical strength, thermal conductivity, chemical resistance |

Mullite bricks are widely used in various industries due to their excellent refractory properties. Here are some common applications:

In the metallurgy industry, both sintered and fused mullite bricks are used in blast furnaces, ladles, and steel - making furnaces. Sintered mullite bricks are often used in less demanding areas, while fused mullite bricks are preferred for areas with high - temperature and high - stress conditions. For example, in a large - scale steel plant, about 30% of the refractory lining in the ladle may be made of sintered mullite bricks, while the critical parts near the molten steel may use fused mullite bricks.

In the glass industry, mullite bricks are used in glass melting furnaces. Fused mullite bricks are especially suitable for areas in contact with molten glass due to their high chemical resistance. A typical glass melting furnace may use around 40% fused mullite bricks in the areas exposed to the most severe conditions.

In the ceramics industry, sintered mullite bricks are commonly used in kilns for firing ceramics. Their good thermal stability helps to maintain a consistent temperature during the firing process. For a medium - sized ceramic kiln, approximately 50% of the refractory lining may be made of sintered mullite bricks.

In conclusion, sintered and fused mullite bricks each have their own unique advantages and are suitable for different industrial applications. By understanding the characteristics of each type, global buyers can make a more informed decision based on their specific needs. Whether you need sintered mullite bricks for general refractory applications or fused mullite bricks for high - performance requirements, our company offers a wide range of high - quality mullite bricks.

Contact our expert sales team today to discuss your requirements and get a customized solution for your refractory needs. Don't miss out on the opportunity to enhance your industrial operations with our top - notch mullite bricks!