For glass manufacturers, furnace stability isn’t just a technical detail—it’s the foundation of productivity, quality consistency, and cost control. In high-temperature environments (often exceeding 1,500°C), even minor refractory degradation can lead to downtime, product defects, or energy waste.

That’s where premium silica brick comes in—not as an optional upgrade, but as a strategic investment. Based on real-world data from over 40 glass plants globally, switching to high-purity silica brick reduced average furnace maintenance intervals by up to 37%, improved glass clarity by 18–22%, and cut fuel consumption by 5–8% within six months of installation.

Many older furnace linings suffer from thermal shock cracking, chemical erosion from molten glass, and structural deformation at sustained high temperatures. These issues aren’t just operational headaches—they directly impact yield, customer satisfaction, and compliance with international standards like ISO 14001 for environmental performance.

| Performance Metric | Standard Silica Brick | Premium Grade (Our Solution) |

|---|---|---|

| Max Operating Temp (°C) | 1,450 | 1,600+ |

| Thermal Shock Resistance | Moderate | Excellent |

| Chemical Stability (Glass Contact) | Low | High |

| Density (g/cm³) | 2.3–2.5 | 1.9–2.1 |

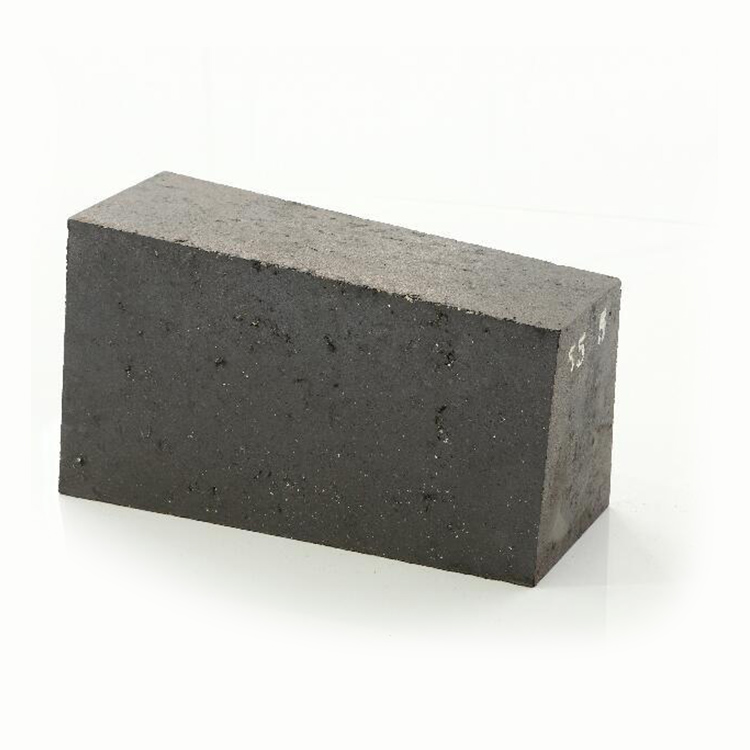

What makes this grade stand out? It’s not just about purity—it’s about microstructure engineering. Our proprietary sintering process ensures uniform grain bonding, minimizing porosity and enhancing resistance to both mechanical stress and chemical attack from soda-lime silicate melts.

We recently worked with a mid-sized flat glass producer in Egypt that was losing ~$12,000/month in unplanned downtime due to frequent lining failures. After replacing their old bricks with our premium silica solution:

“We didn’t expect such a dramatic shift so quickly,” said Ahmed El-Sayed, Head of Production at the plant. “Now we’re able to run longer batches without worrying about kiln instability—and our customers are noticing the difference in finish quality.”

If you're still dealing with inconsistent furnace performance, rising maintenance costs, or declining product quality—especially if your current refractory material is more than 3 years old—you’re likely leaving money on the table.

Let us show you how upgrading to engineered silica brick can transform your production cycle—from raw input to finished product—with measurable gains in efficiency, consistency, and sustainability.

Get a free consultation and customized performance report based on your current setup.

Download Our Free Refractory Optimization Guide