Glass manufacturers face persistent challenges controlling molten glass contamination, which directly impacts product quality and operational efficiency. The fused α-alumina block TY-A addresses these challenges critically with unmatched raw material purity and superior high-temperature performance.

Molten glass purity can be compromised primarily by impurities introduced from refractory linings interacting with the glass melt. Traditional refractory ceramics often contain iron (Fe₂O₃) and titanium oxides (TiO₂) impurities, which catalyze discoloration and bubble formation in glass products. This undermines clarity and mechanical properties, leading to increased waste and customer returns.

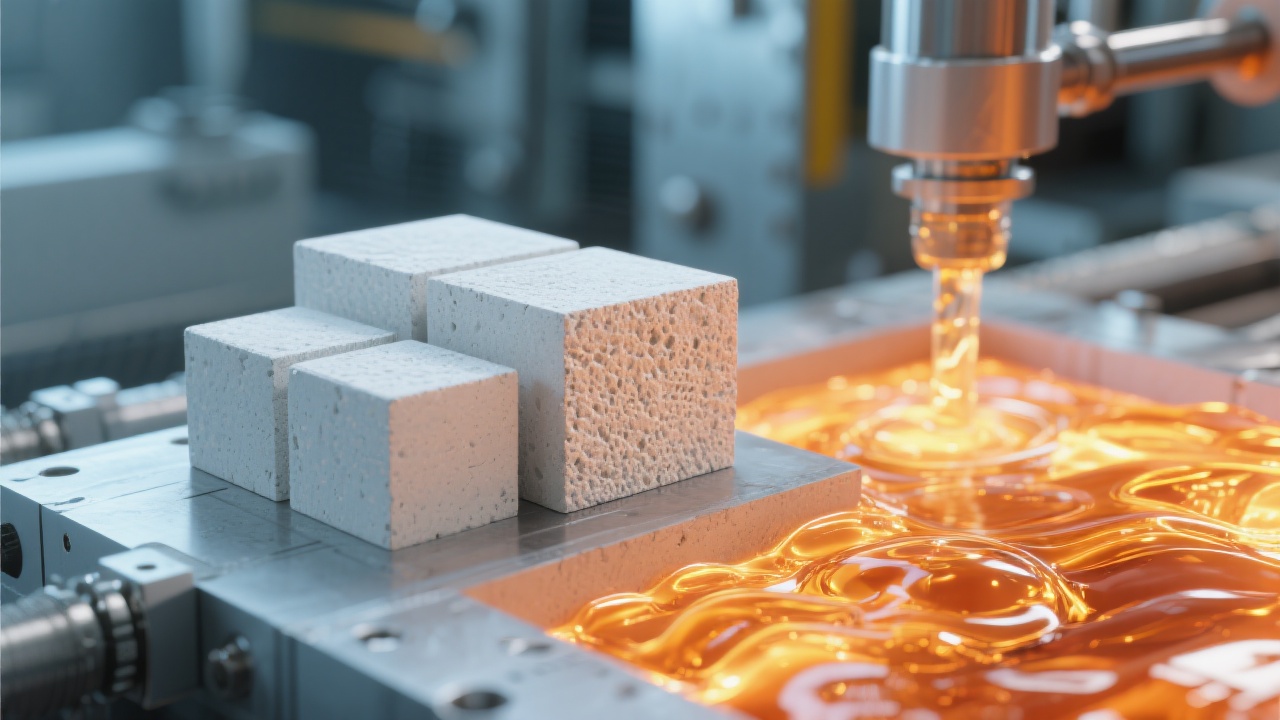

In contrast, the fused α-alumina block TY-A boasts an exceptional alumina (Al₂O₃) content exceeding 98%, completely free from Fe₂O₃ and TiO₂ contaminants. This ultra-high purity base dramatically reduces the risk of impurity diffusion into glass melts, assuring superior optical and structural integrity.

The production of TY-A involves an advanced electrofusion process conducted at 2000°C. This high-temperature melting refines and densifies the alumina grains into an exceptionally compact structure. The resulting microstructure exhibits:

This dense, corrosion-resistant refractory significantly curtails the generation of gases and foreign particles, key contributors to glass liquid contamination.

Field data from leading glass manufacturing clients reveal that the implementation of TY-A fused α-alumina blocks enables:

These operational improvements translate into tangible market advantages, including higher product clarity, consistent customer satisfaction, and reduced overall manufacturing costs.

“Since switching to TY-A, our glass clarity improved noticeably, and production interruptions have decreased. This refractory proved pivotal in elevating our product standards and operational efficiency.” – Verified feedback from a European glass producer.

The intrinsic purity and structural integrity of TY-A fused α-alumina blocks position it as a critical enabler for glass manufacturers aspiring to outpace competition. As product purity becomes a defining selling point, your refractory selection can create differentiated value across the supply chain.

Investing in advanced refractory materials is more than a component upgrade; it's a strategic move to secure product excellence and operational reliability under demanding glass production conditions.