In the glass manufacturing industry, the purity of molten glass is a critical factor that directly impacts the quality of the final products. Contaminants in molten glass can lead to various defects, such as bubbles and impurities, which significantly reduce the market competitiveness of glass products. To address this long - standing pain point, high - purity refractory materials have emerged as an effective solution, and the fused α - alumina block TY - A stands out among them.

The TY - A fused α - alumina block is characterized by its extremely high purity, with an Al₂O₃ content of over 98%. This high purity is the key to its ability to prevent the contamination of molten glass. Impurities such as Fe₂O₃ and TiO₂ are common culprits in glass pollution. In traditional glass manufacturing processes, these impurities can easily mix into the molten glass, causing color changes and bubble formation. However, the TY - A block effectively eliminates this risk. With its ultra - high purity, it acts as a safeguard for the purity of the molten glass, ensuring that the glass produced is of the highest quality.

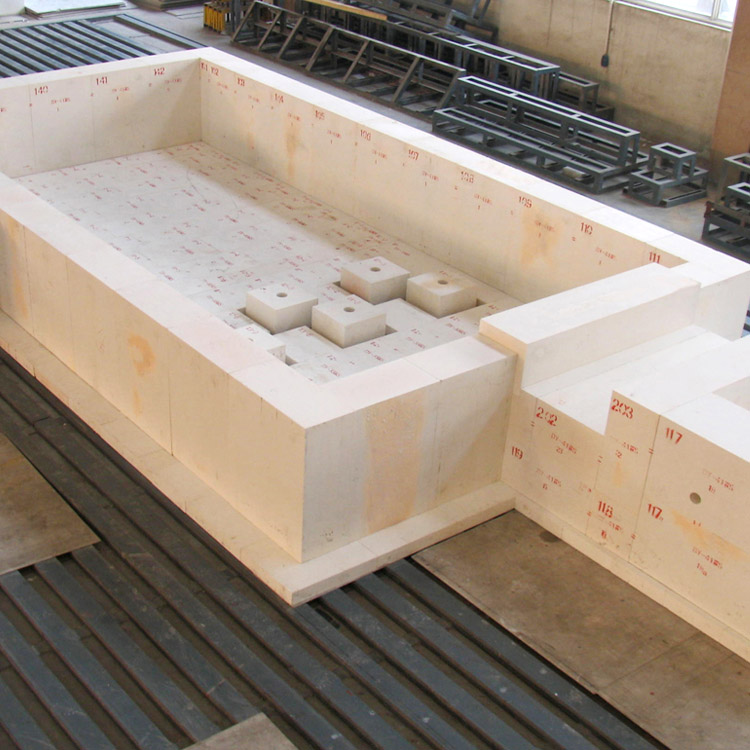

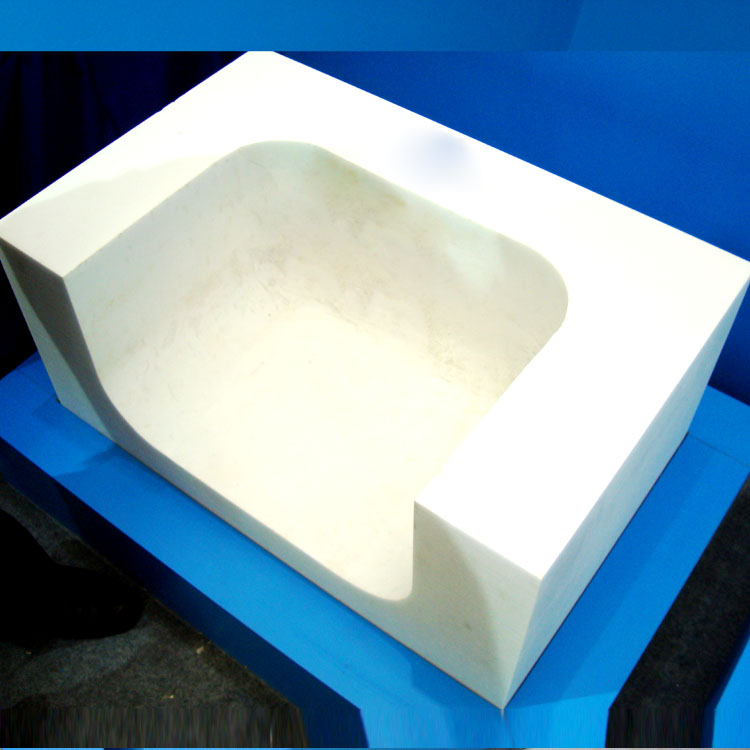

The TY - A block is produced through an electric melting process at 2000°C. This high - temperature process plays a crucial role in building a dense microstructure. At such high temperatures, the raw materials are melted and then solidified, forming a tightly packed structure. This dense structure gives the TY - A block excellent resistance to strong alkalis. In glass manufacturing, the molten glass often contains alkaline substances, and ordinary refractory materials may be corroded by these alkalis, releasing impurities into the molten glass. In contrast, the TY - A block can withstand the erosion of alkalis, maintaining its integrity and preventing contamination.

At a high temperature of 1350°C, the TY - A block shows outstanding corrosion resistance. Test data shows that in this high - temperature environment, the corrosion rate of the TY - A block is significantly lower than that of ordinary refractory materials. For example, while ordinary materials may experience a corrosion rate of about 10% after a certain period of use at 1350°C, the TY - A block's corrosion rate is less than 3%. This significant difference in performance means that the TY - A block can have a much longer service life in glass kilns, reducing the frequency of material replacement and improving production efficiency.

Let's take a look at a typical glass factory application case. Before using the TY - A block, the glass factory faced problems such as high bubble rate and low glass purity. The bubble rate in the molten glass was about 5%, which seriously affected the quality of the final products. After replacing the original refractory materials with the TY - A block, the situation improved significantly. The bubble rate in the molten glass dropped to less than 1%, and the glass purity increased by about 20%. At the same time, the production efficiency also increased. The factory was able to produce more high - quality glass products in the same period, winning a greater market share.

The fused α - alumina block TY - A, with its high purity, dense structure, and excellent high - temperature corrosion resistance, provides an effective solution for glass manufacturing enterprises to improve the purity of molten glass and enhance production efficiency. By using this high - quality refractory material, glass manufacturers can produce cleaner, more bubble - free glass products, thereby gaining a competitive edge in the market. If you are a glass manufacturing enterprise looking to upgrade your production materials and improve product quality, click here to learn more about the fused α - alumina block TY - A and take the first step towards a brighter future in glass manufacturing!