When it comes to choosing refractory materials, many customers find themselves in a quandary. With a plethora of options available in the market, understanding the classification and characteristics of these materials becomes crucial. Among the various refractory products, mullite bricks stand out as a popular choice due to their excellent performance. There are two main types of mullite bricks: sintered mullite bricks and fused mullite bricks. In this article, we will explore the unique features of these two types of mullite bricks to help you make an informed decision.

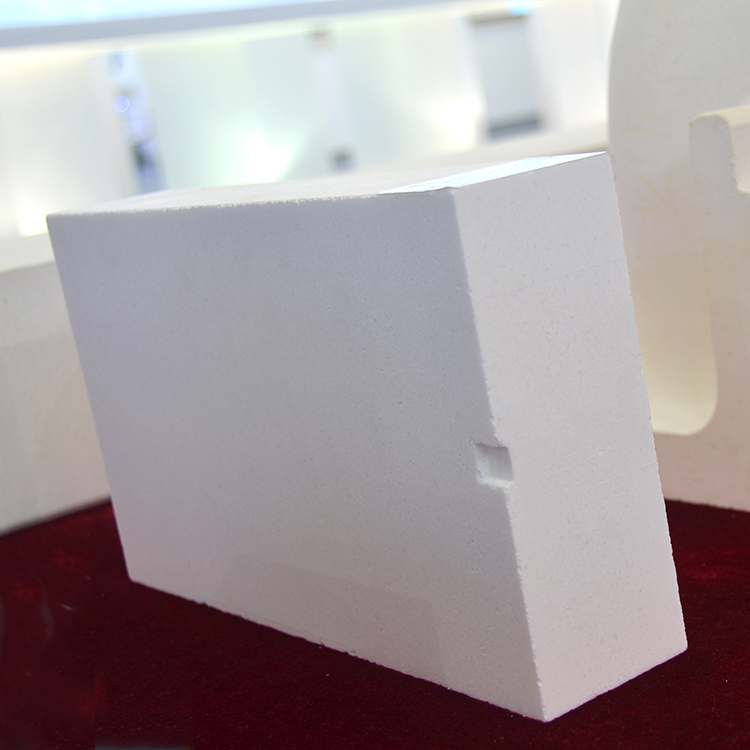

The raw materials for sintered mullite bricks mainly include high - alumina bauxite, clay, and other natural minerals. These raw materials are carefully selected and proportioned to ensure the quality of the final product. The production process of sintered mullite bricks involves several steps. First, the raw materials are crushed and ground into fine powder. Then, they are mixed with a certain amount of binder and water to form a homogeneous mixture. After that, the mixture is molded into the desired shape under high pressure. Finally, the molded bricks are sintered at a high temperature of about 1700 - 1800°C in a kiln.

Sintered mullite bricks have several remarkable performance characteristics. They have high refractoriness, with a refractoriness under load typically above 1600°C. They also possess good thermal shock resistance, which means they can withstand sudden temperature changes without cracking. In addition, their chemical stability is excellent, making them resistant to the corrosion of various slag and molten metals.

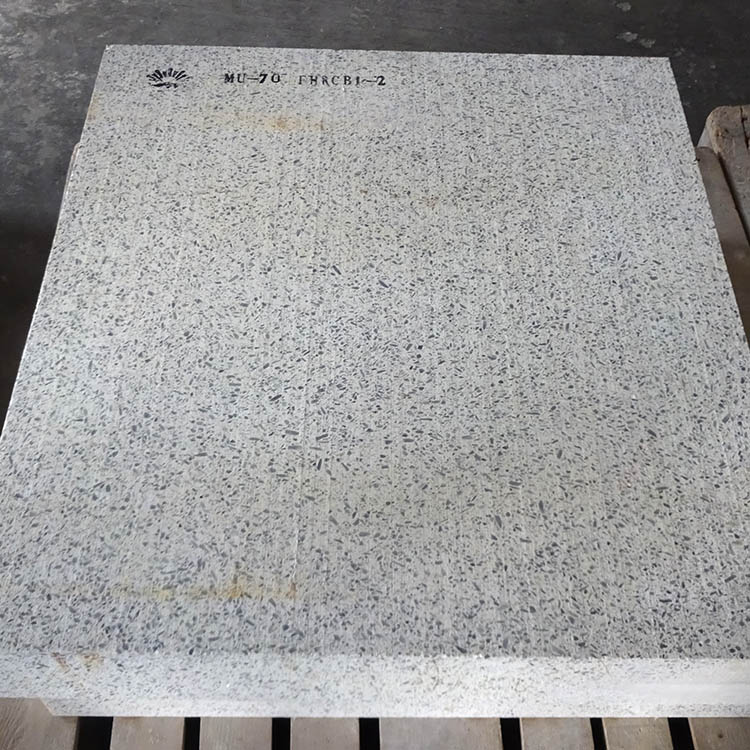

Fused mullite bricks are made from high - purity alumina and silica raw materials. The production process of fused mullite bricks is quite different from that of sintered mullite bricks. In the production of fused mullite bricks, the raw materials are first melted in an electric arc furnace at a very high temperature of around 2000 - 2200°C. After melting, the molten material is poured into a mold and allowed to cool and solidify slowly.

Fused mullite bricks have outstanding performance in terms of density and strength. They have a higher density compared to sintered mullite bricks, usually around 3.0 - 3.2 g/cm³, which gives them better wear resistance. Their high - temperature strength is also superior, enabling them to maintain their shape and performance under extremely high - temperature conditions. Moreover, their thermal conductivity is relatively low, which can help save energy in high - temperature applications.

| Aspect | Sintered Mullite Bricks | Fused Mullite Bricks |

|---|---|---|

| Raw Materials | High - alumina bauxite, clay, etc. | High - purity alumina and silica |

| Production Process | Crushing, mixing, molding, sintering at 1700 - 1800°C | Melting in an electric arc furnace at 2000 - 2200°C, pouring and solidifying |

| Density | Around 2.6 - 2.8 g/cm³ | Around 3.0 - 3.2 g/cm³ |

| Thermal Shock Resistance | Good | Relatively poor |

| High - temperature Strength | Moderate | High |

In the metallurgical industry, fused mullite bricks are often used in the lining of blast furnaces and steel - making furnaces due to their high density and excellent high - temperature strength. Sintered mullite bricks are suitable for the pre - heating zone of kilns because of their good thermal shock resistance. In the glass industry, both types of mullite bricks can be used in the melting furnaces. Sintered mullite bricks are preferred in areas where thermal shock resistance is crucial, while fused mullite bricks are used in areas with high - temperature and high - pressure requirements. In the ceramic industry, sintered mullite bricks are widely used in tunnel kilns and roller kilns for their cost - effectiveness and good performance.

In summary, sintered mullite bricks and fused mullite bricks have their own unique characteristics and application scenarios. Sintered mullite bricks are known for their good thermal shock resistance and chemical stability, while fused mullite bricks are famous for their high density and excellent high - temperature strength. When choosing mullite bricks, it is essential to consider your specific requirements and application scenarios.

Our company offers a wide range of sintered and fused mullite bricks that can meet your different needs. Our professional team can provide you with detailed technical support and help you make the right choice. Don't hesitate to contact us to learn more about our mullite bricks and start enhancing your high - temperature applications today!