.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

In the glass industry, production efficiency is a critical factor that directly impacts profitability. Traditional refractory materials often struggle to meet the high - temperature and chemical - resistant requirements of glass production, leading to frequent material replacement and production interruptions. This is where zircon mullite bricks come into play as a revolutionary solution.

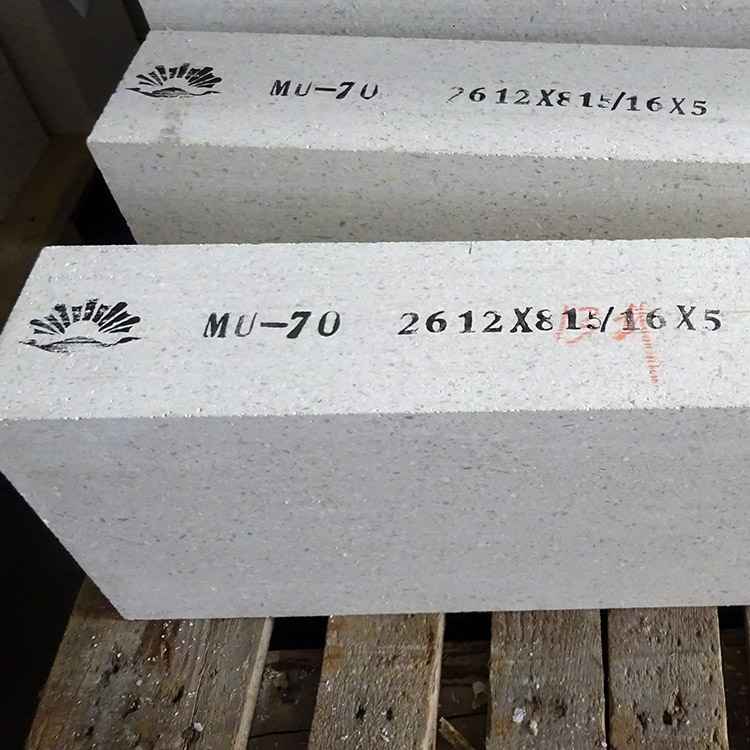

Zircon mullite bricks are made from high - quality raw materials such as zircon sand and mullite. The manufacturing process involves precise control of temperature and pressure to ensure the bricks have a dense structure and high purity. These bricks are known for their excellent thermal shock resistance, anti - spalling properties, and high corrosion resistance.

Compared with traditional refractory materials, zircon mullite bricks have several significant advantages. Firstly, they can withstand higher temperatures without significant deformation. In a glass melting furnace with an average operating temperature of around 1500 - 1600°C, traditional refractory materials may start to show signs of damage after about 6 - 8 months of use. In contrast, zircon mullite bricks can last up to 18 - 24 months, reducing the frequency of material replacement by 50% - 70%.

Secondly, their excellent anti - spalling properties ensure that the inner lining of the furnace remains intact. This reduces the risk of glass contamination caused by falling refractory fragments, which can improve the quality of the glass products by up to 20%.

Thirdly, zircon mullite bricks have strong corrosion resistance against various glass - forming chemicals. This helps to maintain the integrity of the furnace structure and reduces the need for frequent repairs, thereby ensuring the continuity of production.

A glass manufacturing company in Europe was facing production efficiency issues due to the frequent replacement of traditional refractory materials. After switching to zircon mullite bricks, they witnessed a remarkable improvement. The production interruption frequency decreased from an average of 4 times a year to only 1 time a year. This led to an increase in annual production capacity by approximately 15%. At the same time, the cost of material replacement and maintenance was reduced by about 40%, resulting in significant economic benefits.

.jpg)

Another glass factory in Asia reported that after using zircon mullite bricks, the quality of their glass products improved significantly. The rejection rate decreased from 8% to 3%, which not only saved production costs but also enhanced the company's market competitiveness.

Zircon mullite bricks have proven to be a game - changer in the glass industry. They can significantly improve production efficiency, reduce costs, and enhance product quality. If you are looking for a reliable solution to boost your glass production efficiency and achieve greater economic benefits, consider using zircon mullite bricks. Contact us today to learn more about how our zircon mullite bricks can transform your glass manufacturing process!

Don't miss out on the opportunity to revolutionize your glass production. Click here to get in touch with our experts and start your journey towards higher efficiency and profitability.