In the glass industry, even minor impurities in raw materials can lead to significant defects—especially in high-quality products like optical glass or specialty containers. One of the most persistent challenges? Gas bubble formation caused by iron oxide (Fe₂O₃) and titanium dioxide (TiO₂) contamination during melting. These contaminants not only reduce product transparency but also increase production downtime and waste.

TY-A is engineered with an Al₂O₃ content exceeding 98%, which drastically reduces harmful impurities such as Fe₂O₃ (<0.5%) and TiO₂ (<0.3%). In real-world applications, this means up to 40–60% fewer gas bubbles compared to traditional fused alumina blocks. For manufacturers producing premium glassware, this translates directly into higher yield rates and improved surface finish quality.

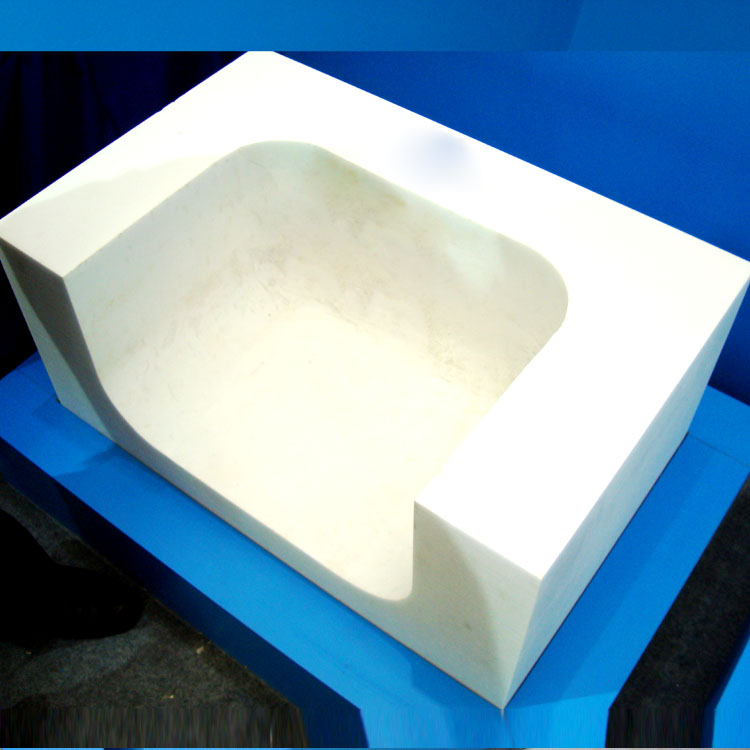

Unlike conventional sintered alumina, TY-A undergoes a precise 2000°C electrofusion process that creates a dense, uniform microstructure. This structure offers exceptional resistance to alkali attack at temperatures above 1350°C—critical for long-term performance in glass tanks where Na₂O and K₂O are constantly present. Field tests from European glass producers show a 30% longer refractory life when switching to TY-A, reducing maintenance frequency and operational disruption.

💡 Pro Tip: When choosing refractories, don’t just look at cost per ton—evaluate total lifecycle value. TY-A may have a slightly higher upfront cost, but its durability and purity deliver measurable ROI through reduced rework, lower energy consumption, and consistent output quality.

A case study from a major Middle Eastern glass manufacturer revealed that after replacing standard alumina bricks with TY-A, they achieved:

These metrics aren’t just numbers—they represent real gains in customer satisfaction, production efficiency, and market competitiveness.

Let your glass be cleaner, stronger, and more competitive—from the first melt to the final batch.

Try TY-A Today – Get a Free Sample & Technical Data Sheet