In the highly competitive global glass industry, enhancing production efficiency and reducing costs are crucial factors for enterprises to gain a competitive edge. One key material that has emerged as a game - changer in this regard is Zirconia - Mullite Bricks. Let's delve into how these bricks can revolutionize glass production.

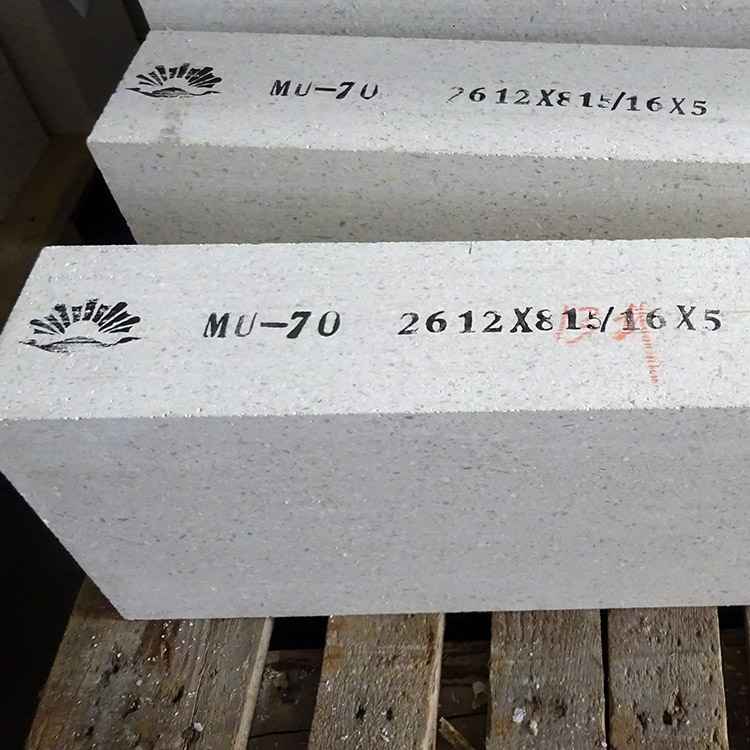

Zirconia - Mullite Bricks are high - performance refractory materials made primarily from fused zirconia - mullite and sintered alumina. With a high degree of compactness and purity, these bricks possess a unique combination of properties that make them ideal for the harsh environments of glass manufacturing.

First and foremost, their excellent thermal shock stability is remarkable. In glass furnaces, where rapid temperature changes are common, Zirconia - Mullite Bricks can withstand sudden temperature variations without cracking or spalling. Tests have shown that they can endure temperature differences of up to 300°C without significant damage, which is far superior to many traditional refractory materials. This means fewer replacements and less downtime for furnace maintenance.

Secondly, they have strong anti - spalling properties. During the repeated heating and cooling cycles in the glass - making process, the bricks maintain their structural integrity, preventing fragments from falling into the molten glass. This helps to ensure the quality of the glass products and reduces the risk of production defects.

Finally, their high resistance to corrosion is a major advantage. Glass melts often contain various corrosive substances, but Zirconia - Mullite Bricks can resist the attack of these chemicals for an extended period. Studies indicate that they can last up to 2 - 3 times longer than some traditional refractory bricks in highly corrosive environments, which significantly reduces the frequency of brick replacement and lowers long - term costs.

When compared with traditional refractory materials, Zirconia - Mullite Bricks clearly stand out. Traditional materials may have lower initial costs, but they often require more frequent replacements due to poor thermal shock stability, spalling, and corrosion resistance. This leads to higher overall costs in the long run, including labor costs for replacement and production losses during downtime.

Many glass manufacturers around the world have already reaped the benefits of using Zirconia - Mullite Bricks. For example, a large - scale glass factory in Europe switched to Zirconia - Mullite Bricks in their furnaces. As a result, they were able to increase their production efficiency by 15% due to reduced downtime for maintenance. Additionally, they saved approximately 20% on refractory material costs over a period of one year because of the longer service life of the bricks.

Another glass enterprise in Asia reported that after using these bricks, the quality of their glass products improved significantly, with a reduction in defect rates by up to 10%. This not only enhanced their market competitiveness but also increased customer satisfaction.

Zirconia - Mullite Bricks are undoubtedly a key solution for glass manufacturers looking to improve production efficiency and achieve greater economic benefits. Their unique properties, combined with proven real - world results, make them a reliable choice for the glass industry.

If you're looking to take your glass production to the next level, don't miss out on the advantages of Zirconia - Mullite Bricks. Contact us today to learn more about how these bricks can transform your manufacturing process and boost your bottom line!