The global refractory materials market has been experiencing significant growth in recent years. According to market research, the market size is expected to reach $XX billion by 2025, growing at a CAGR of XX% from 2020 to 2025. This growth is mainly driven by the increasing demand from industries such as steel, cement, glass, and non - ferrous metals. These industries require high - performance refractory materials to withstand extreme temperatures, chemical corrosion, and mechanical stress during their production processes. In this context, directly bonded magnesia - chrome bricks have emerged as a key solution, playing an important role in meeting the evolving needs of the market.

Traditional magnesia - chrome bricks, such as non - fired magnesia - chrome bricks, are produced through a series of processes including raw material preparation, mixing, molding, and heat treatment. They have certain advantages, such as relatively low cost and good initial resistance to corrosion. However, they also have obvious limitations. For example, their high - temperature strength is relatively poor, with a refractoriness under load typically around XX°C, and they are prone to spalling and cracking under long - term high - temperature and high - pressure conditions. In addition, the environmental impact of traditional magnesia - chrome bricks is also a concern, as they may release harmful substances during use.

Directly bonded magnesia - chrome bricks are characterized by their excellent high - temperature performance. They have a refractoriness under load of up to XX°C, which is significantly higher than that of traditional magnesia - chrome bricks. Their thermal shock resistance is also outstanding, able to withstand rapid temperature changes without significant damage. In terms of chemical corrosion resistance, they can effectively resist the erosion of various slags and gases in industrial furnaces. For example, in the steelmaking industry, directly bonded magnesia - chrome bricks can reduce the corrosion rate by XX% compared with traditional bricks, greatly extending the service life of the furnace lining.

The emergence of directly bonded magnesia - chrome bricks has had a profound impact on the refractory materials market. It has promoted the technological upgrading of the industry. Many manufacturers are now investing in research and development to improve the production process of directly bonded magnesia - chrome bricks. In terms of market share, the proportion of directly bonded magnesia - chrome bricks in the global refractory materials market has increased from XX% in 2020 to XX% in 2023, and it is expected to continue to grow in the future. This has also changed the competitive landscape of the market, with companies that can produce high - quality directly bonded magnesia - chrome bricks gaining a competitive edge.

Directly bonded magnesia - chrome bricks have been widely used in various industries. In the cement industry, a large cement plant in Europe reported that after using directly bonded magnesia - chrome bricks in its rotary kiln, the maintenance cycle of the kiln lining was extended from XX months to XX months, and the production efficiency was increased by XX%. In the glass industry, a glass manufacturer in Asia found that the use of directly bonded magnesia - chrome bricks reduced the frequency of furnace repairs, saving production costs by approximately XX%. Customers generally praised the high performance and long - term reliability of directly bonded magnesia - chrome bricks.

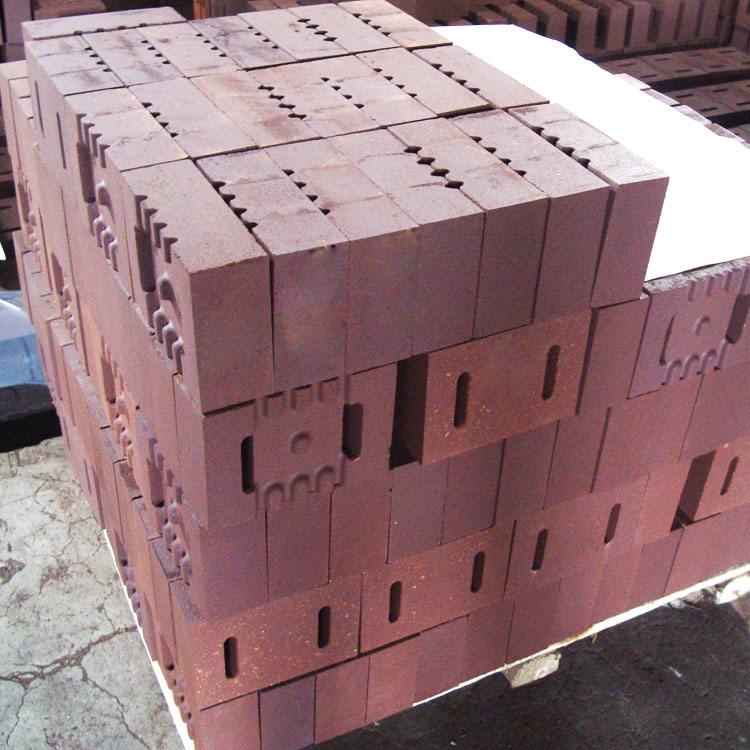

.jpg)

Looking ahead, directly bonded magnesia - chrome bricks are expected to lead the refractory materials industry towards high - performance and high - quality development. With the continuous improvement of production technology, the performance of directly bonded magnesia - chrome bricks will be further enhanced. The market demand will also continue to grow, especially in emerging economies where industrialization is accelerating. As environmental requirements become more stringent, manufacturers will also focus on reducing the environmental impact of directly bonded magnesia - chrome bricks during production and use.

Our directly bonded magnesia - chrome bricks offer unparalleled performance and reliability. Contact us today to discuss how our products can meet your specific needs and boost your production efficiency. Don't miss out on this opportunity to revolutionize your refractory materials!