The global refractory materials market has witnessed significant growth in recent years, driven by the expansion of industries such as steel, cement, and glass. As these industries continue to evolve, the demand for high - performance refractory materials is on the rise. The market now requires materials that can withstand higher temperatures, have better chemical resistance, and longer service lives. In this context, directly bonded magnesia - chrome bricks are emerging as a crucial solution to meet these evolving needs.

Traditional magnesia - chrome bricks, such as non - fired magnesia - chrome bricks, have been widely used in the past. The production process of non - fired magnesia - chrome bricks typically involves mixing magnesia and chrome ore with a binder, followed by molding and drying. These bricks have some advantages, including relatively low production costs and certain levels of heat resistance. However, they also have significant limitations. For example, their strength at high temperatures is relatively low, and their chemical stability is not ideal in some harsh environments. Statistics show that in high - temperature industrial furnaces, the service life of non - fired magnesia - chrome bricks is about 3 - 6 months, which is far from meeting the long - term stable operation requirements of modern industries.

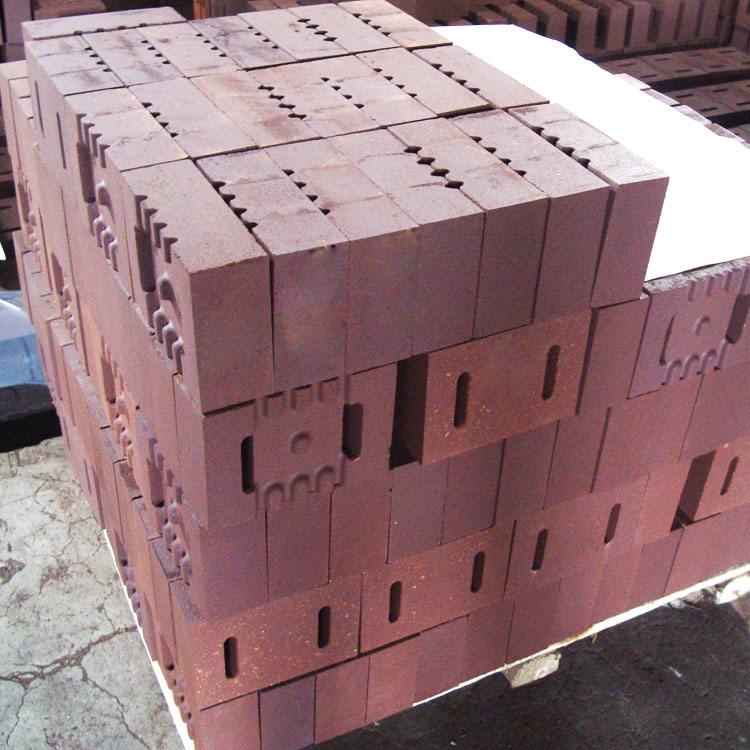

.jpg)

Directly bonded magnesia - chrome bricks offer outstanding performance. They have high - temperature resistance, capable of withstanding temperatures up to 1800°C, which is significantly higher than traditional magnesia - chrome bricks. Their high strength ensures that they can maintain stable physical properties under high - pressure and high - temperature conditions. In addition, directly bonded magnesia - chrome bricks have excellent chemical stability, showing strong resistance to corrosion from various slags and gases. These performance characteristics perfectly meet the market's demand for high - performance refractory materials. For example, in the steelmaking industry, directly bonded magnesia - chrome bricks can effectively improve the lining life of converters, reducing the frequency of furnace repairs and improving production efficiency.

The emergence of directly bonded magnesia - chrome bricks is driving the technological upgrade of the refractory materials industry. Their superior performance is changing the market pattern, forcing traditional refractory material manufacturers to invest in research and development to improve product quality. According to market research, the market share of directly bonded magnesia - chrome bricks has been increasing year by year, reaching 30% in the global refractory materials market in recent years. This indicates that directly bonded magnesia - chrome bricks are gradually becoming the mainstream product in the market.

Many global companies have adopted directly bonded magnesia - chrome bricks and have provided positive feedback. For instance, a large - scale steel company in Europe reported that after using directly bonded magnesia - chrome bricks in its blast furnace, the furnace lining's service life increased from 8 months to 18 months, reducing maintenance costs by 30%. Another glass manufacturing enterprise in Asia found that the use of directly bonded magnesia - chrome bricks improved the quality of glass products and reduced energy consumption by 20%.

With the continuous development of global industries, the demand for high - performance refractory materials will continue to grow. Directly bonded magnesia - chrome bricks, with their excellent performance and market competitiveness, are expected to play an even more important role in the future. The industry trend is towards high - performance, energy - saving, and environmentally friendly products, and directly bonded magnesia - chrome bricks fully meet these requirements. At the same time, various countries' policies are also supporting the development of high - quality refractory materials, providing a good policy environment for the development of directly bonded magnesia - chrome bricks.

Don't miss the opportunity to enhance your business's competitiveness in the refractory materials market. Our directly bonded magnesia - chrome bricks offer high - performance, long - lasting solutions. Contact us today to learn more about how our products can meet your specific needs and take your business to the next level!