In the glass manufacturing industry, the performance of refractory materials directly impacts production efficiency, product quality, and equipment longevity. Traditional refractories often face challenges such as chemical corrosion, thermal shock, and structural degradation under extreme conditions. To address these issues, AZS33 fusion cast blocks have emerged as a high-performance solution, offering exceptional resistance to both high temperatures and corrosive glass melt.

AZS33 is composed primarily of aluminum oxide (Al₂O₃) and zirconium silicate (ZrSiO₄), with a precise ratio of 33% ZrO₂, 55% Al₂O₃, and 12% SiO₂. This unique composition ensures excellent thermal stability and chemical inertness. The addition of zirconium dioxide significantly enhances the material's resistance to alkali and silica-based melts commonly found in glass production.

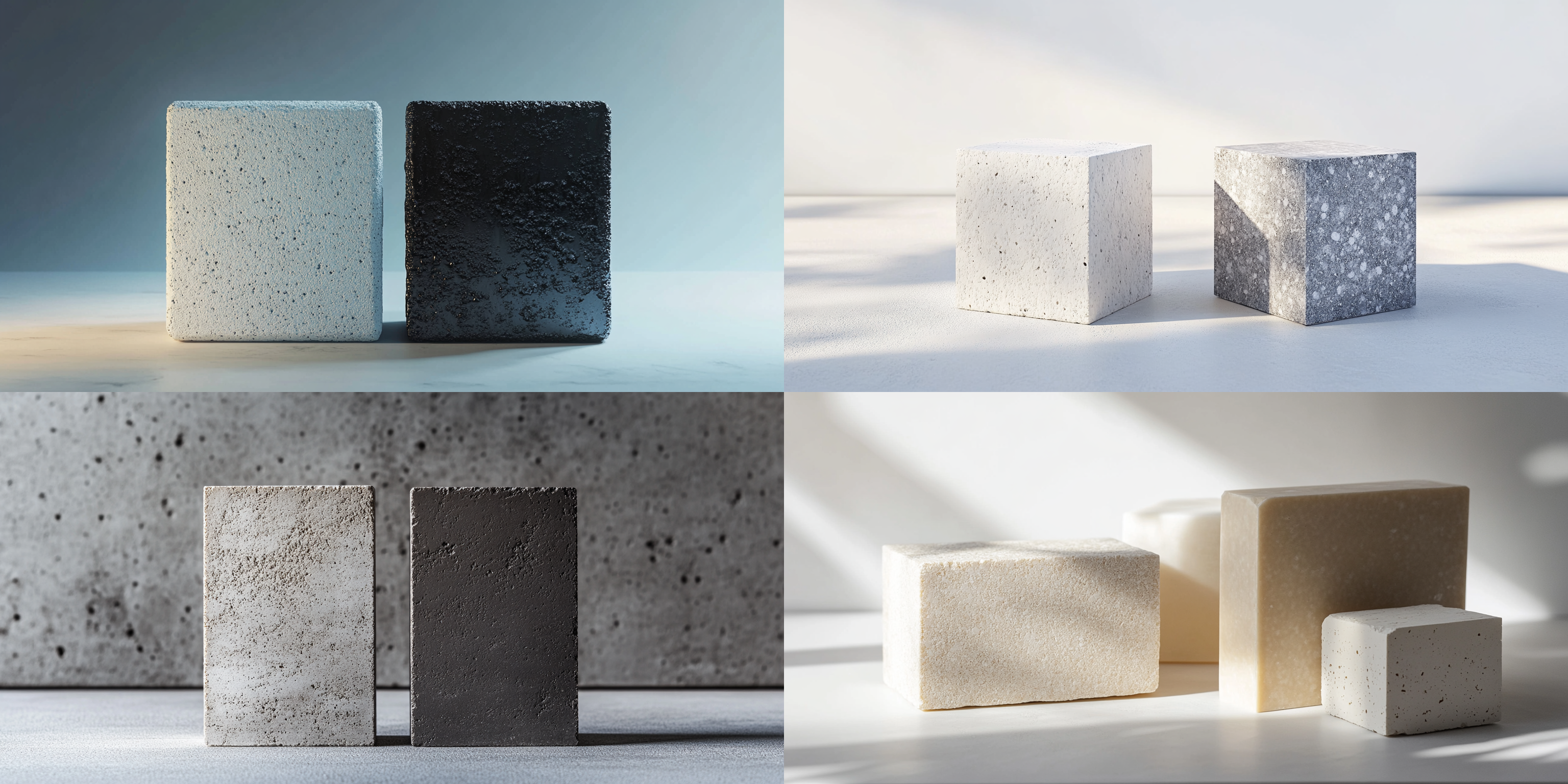

Compared to traditional fireclay bricks or fused mullite bricks, AZS33 exhibits superior mechanical strength and lower porosity, making it more resistant to molten glass penetration and erosion. According to internal testing data, AZS33 has a bulk density of 3.4 g/cm³ and a porosity of less than 1.5%, outperforming conventional refractories by over 30% in durability.

The dense microstructure of AZS33 is formed through a controlled melting and casting process that minimizes grain boundaries and voids. This structure not only improves thermal conductivity but also prevents the formation of cracks under rapid temperature changes. In laboratory tests, AZS33 showed no significant weight loss after being exposed to molten glass at 1600°C for 100 hours, whereas traditional refractories lost up to 8% of their mass under the same conditions.

This resistance to chemical attack is particularly crucial in areas where glass melt comes into direct contact with refractory linings, such as the melting zone, regenerator, and forehearth of the furnace. AZS33’s ability to maintain its integrity in these harsh environments reduces downtime and maintenance costs, ultimately improving overall operational efficiency.

AZS33 fusion cast blocks are widely used in critical sections of the glass melting furnace, including the bottom, side walls, and throat area. These parts are subjected to the highest levels of thermal stress and chemical exposure. By using AZS33, manufacturers can achieve longer lining life and reduced refractory consumption.

For example, a major glass producer in Europe replaced its conventional refractories with AZS33 in the melting zone of its furnace. After one year of operation, the refractory lining showed minimal signs of wear, compared to the frequent replacements required with older materials. This resulted in a 25% increase in production output and a 20% reduction in energy consumption due to improved heat retention.

Several case studies from global glass manufacturers confirm the effectiveness of AZS33 in real-world applications. One North American plant reported a 35% decrease in refractory replacement frequency after switching to AZS33, leading to significant cost savings and increased production uptime. Another manufacturer in Southeast Asia noted a 15% improvement in glass clarity due to reduced impurities from refractory erosion.

These results highlight the long-term value of AZS33, not just in terms of performance, but also in supporting sustainable and efficient glass production practices.

AZS33 fusion cast blocks represent a significant advancement in refractory technology for the glass industry. With its optimized composition, dense microstructure, and proven performance in high-stress environments, AZS33 offers a reliable and cost-effective solution for modern glass manufacturing.

For glass producers seeking to enhance efficiency, reduce maintenance, and improve product quality, AZS33 is a scientifically engineered choice that delivers measurable benefits. Discover how this advanced refractory material can transform your production process today.

Explore AZS33 Solutions Now