Industrial high-temperature equipment is constantly exposed to extreme conditions such as high heat, chemical corrosion, and mechanical stress. These challenges can significantly reduce the lifespan of critical components and lead to costly downtime. To address these issues, industries are increasingly turning to advanced refractory materials like corrosion-resistant sillimanite bricks, which offer exceptional performance in harsh environments.

Sillimanite bricks are made from the natural mineral sillimanite, which undergoes a high-temperature sintering process. This transformation results in a material composed primarily of mullite and free silica, giving it outstanding thermal and mechanical properties. With a refractoriness of 1770–1830°C, these bricks are ideal for applications where extreme heat resistance is required.

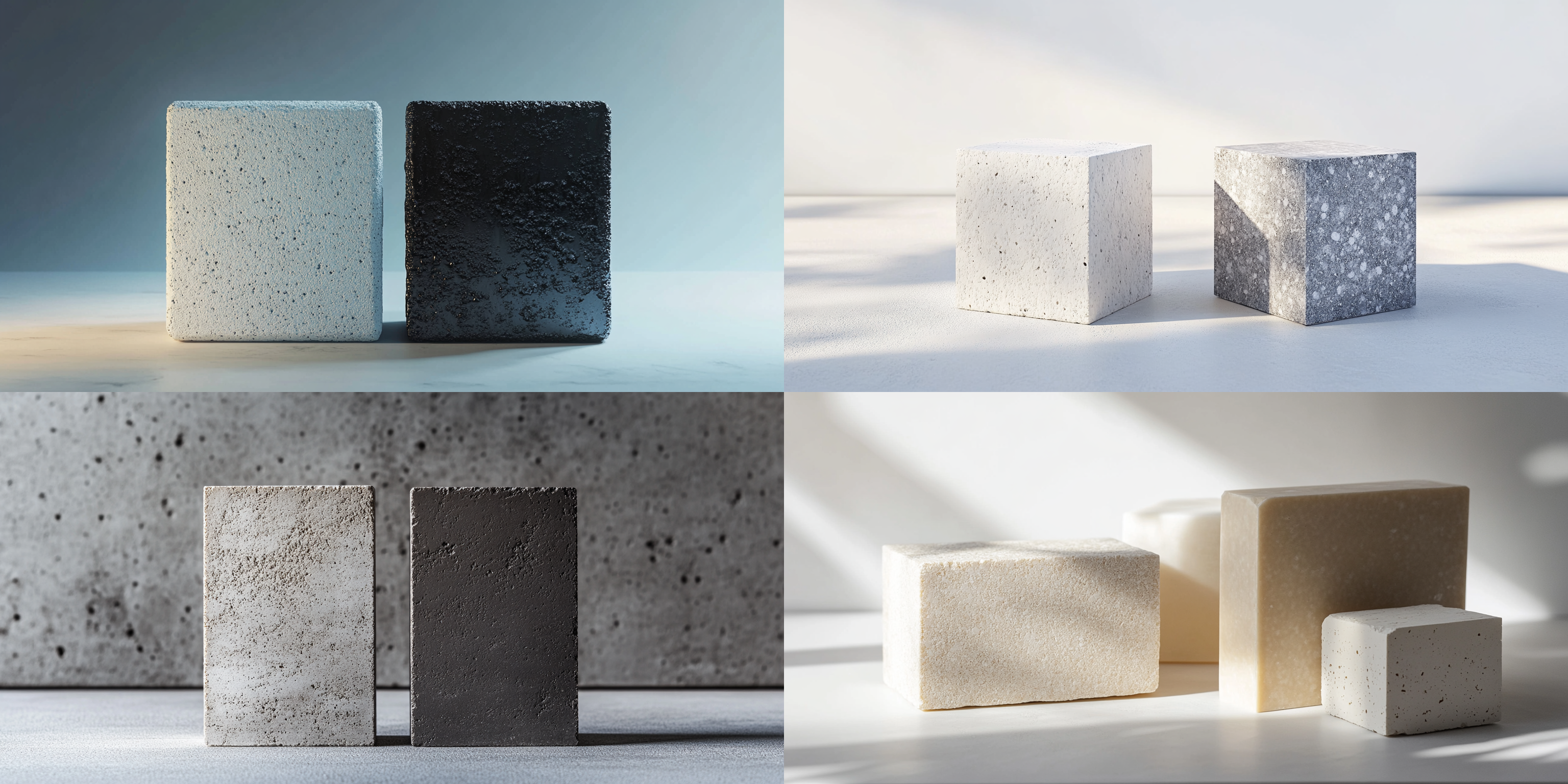

Sillimanite bricks are known for their excellent thermal shock resistance, low thermal expansion coefficient, and high wear resistance at elevated temperatures. Below is a summary of their key characteristics:

| Property | Value |

|---|---|

| Refractoriness | 1770 - 1830°C |

| Thermal Expansion Coefficient | ≤ 0.5% |

| Cold Crushing Strength | ≥ 80 MPa |

| Porosity | ≤ 18% |

.jpg)

Sillimanite bricks are widely used in high-temperature industrial applications, particularly in glass furnaces and blast furnace linings. Their ability to withstand chemical erosion and thermal cycling makes them an ideal choice for environments where traditional refractories may degrade quickly.

For example, in a major glass manufacturing plant in Europe, the installation of sillimanite bricks in the melting zone reduced refractory wear by over 30%, extending the furnace's service life and improving overall production efficiency. Similarly, in a steelmaking facility in Asia, the use of these bricks in the high-temperature zones of the blast furnace led to a significant reduction in maintenance costs and unplanned downtime.

By using corrosion-resistant sillimanite bricks, manufacturers can achieve multiple benefits, including:

.jpg)

In the decision-making phase of industrial procurement, trust and reliability are crucial. Sillimanite bricks have proven their effectiveness across various sectors, offering a robust solution for high-temperature applications. With their superior performance and long-term cost savings, they are becoming a preferred choice for global manufacturers seeking durable and efficient refractory materials.

Don't let high-temperature challenges compromise your production efficiency. Invest in corrosion-resistant sillimanite bricks and ensure your industrial equipment operates at peak performance. Contact us today to learn more about how we can help you build a stronger, more resilient production line.