In the demanding fields of professional glass furnaces and the nuclear industry, the selection of materials is crucial. These industries require materials that can withstand extreme conditions, such as high temperatures, chemical corrosion, and mechanical stress. High-density zircon bricks have emerged as a solution that offers distinct advantages over similar products, providing a unique difference in performance and application.

High-density zircon bricks are renowned for their exceptional performance in several key areas. Firstly, they exhibit outstanding resistance to alkaline glass corrosion. In glass manufacturing, alkaline glass can cause significant damage to furnace linings. However, high-density zircon bricks have been tested to resist corrosion rates up to 80% lower than many other comparable materials. This means longer service life for glass furnaces, reducing maintenance costs and downtime.

Secondly, high-density zircon bricks demonstrate excellent high-temperature creep resistance. At high temperatures, many materials tend to deform under load over time. But high-density zircon bricks can maintain their shape and structural integrity even at temperatures up to 1600°C, with a creep rate of less than 0.5% after 100 hours of continuous use. This stability is essential for ensuring the long-term performance of glass furnaces and nuclear facilities.

In addition, high-density zircon bricks have high high-temperature flexural strength. They can withstand bending forces at high temperatures, which is crucial for applications where the material may be subject to mechanical stress. Tests have shown that these bricks can withstand a flexural strength of up to 20 MPa at 1400°C, providing reliable support in harsh environments.

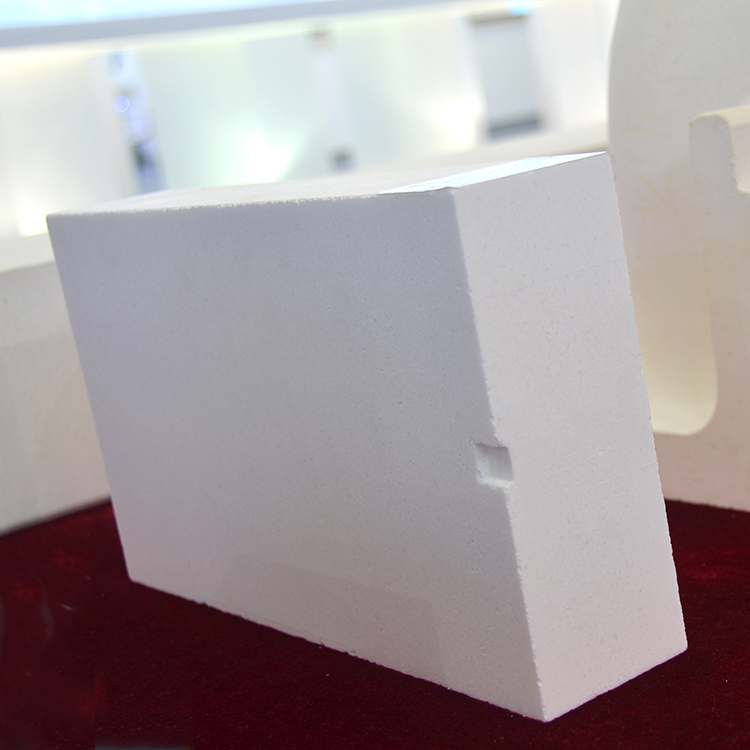

High-density zircon bricks are ideal for use in professional glass furnaces and the nuclear industry. In glass manufacturing, they can be used in various parts of the furnace, including the bottom of the melting tank and the forehearth of alkali-free glass furnaces. Their excellent performance ensures the quality and stability of the glass production process.

.jpg)

In the nuclear industry, high-density zircon bricks are valued for their ability to control trace impurities. They have extremely low levels of impurities, which is critical for maintaining the purity and safety of nuclear processes. This makes them a reliable choice for use in nuclear reactors and related facilities.

Numerous case studies have demonstrated the reliability of high-density zircon bricks. For example, in a large-scale glass manufacturing plant, the use of high-density zircon bricks in the melting tank extended the furnace's service life by 30% compared to previous materials, resulting in significant cost savings. In the nuclear industry, these bricks have been used in several reactors, where they have maintained their performance and integrity over long periods of operation.

High-density zircon bricks offer a unique difference solution for professional glass furnaces and the nuclear industry. Their outstanding performance in resistance to alkaline glass corrosion, high-temperature creep, and high-temperature flexural strength, combined with their ability to control trace impurities, make them a superior choice over similar products. By choosing high-density zircon bricks, businesses can gain a competitive edge, improve the efficiency of their operations, and achieve sustainable growth.

If you are interested in learning more about how high-density zircon bricks can benefit your business, please contact us today. Our team of experts is ready to provide you with detailed information and customized solutions.

Discover the unique advantages of high-density zircon bricks for your professional glass furnace or nuclear project. Contact us for more information and start your journey towards enhanced performance and cost savings.